Depalletizing in intralogistics

automatic layer seperation

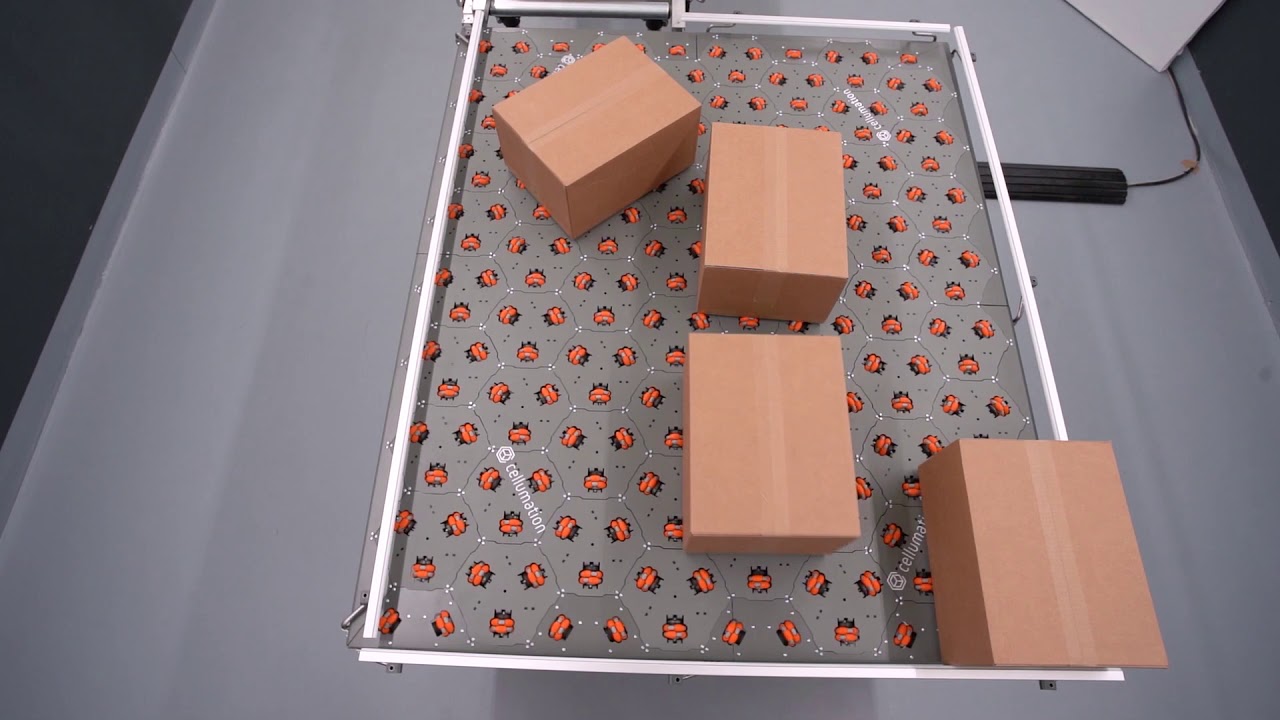

Thanks to its ability to work in the smallest possible space, move objects in all directions, and its flexible control, the celluveyor is the ideal layer separation system for automated depalletizing applications.

Space-saving depalletizing, efficient and smart thanks to hexagonal robot cells

Pallet layers are indispensable in the transportation of goods. Goods of different or the same type are grouped together on them pallets in order to achieve low transport costs for high transport volumes. In further processing, these layers must be separated and thus depalletized.

Pallet transportation layers are is particularly common in the food sector. There, heterogeneous products are produced and shipped. However, individual supermarkets do not receive products by the pallet, but very individually. Currently in many cases where the celluveyor is not used, these layers are often handled manually. This results in the special challenge The special challenge is about of being able to process different shapes and sizes simultaneously as part of an automation system.

The intelligent solution for this challenge is obvious and is realized by our celluveyor Technology. The cv.DEPAL meets the necessary requirements. The hexagonally arranged cells enable efficient material flows and smooth, automatic separation in the depalletizing process. We can also provide mixing pallets rotate the objects of mixed pallets according to the requirements of the customer for subsequent automated operations for subsequent automated operations.

However, in many production halls, supermarkets or storage areas there is not much space, so another requirement is a small size:

The cv.DEPAL requires only 5% of the area of comparable conveyor systems. The modular design of the conveyor system allows for 6-fold redundancy and, should get things serious, cell replacement in under 5 minutes. The only tool needed is a screwdriver.

What is the difference to conventional layer separation systems?

Conventional systems for layer separation require a lot of space, consist of many different individual components , operate according to a passive system and cannot react individually to individual objects. Consist of many different components. Due to the mechanical complexity and dimensions, maintenance of existing systems is time-consuming and expensive. After installation, no changes can be made to these systems without changing the system structure. This has many disadvantages, especially in terms of process speed. This is completely different with the celluveyor.

The celluveyor does not require any changeover times for different pallet layers. The celluveyor recognizes the individual objects automatically and reacts instinctively through artificial intelligence. It can also depalletize to different outputs depending on the specification, split to up to 3 outputs, transfer to the output depending on the desired orientation (short side ahead or long side ahead) and sort.

Highly efficient in the smallest space

The celluveyor offers simple and fast assembly thanks to its highly modular design, which enables space savings of up to 95% compared to other systems. We dynamically and individually influence control the object movement. This is made possible by an intelligent vision system above the celluveyor cells, which individually controls the drives of the omnidirectional wheels.

Later adaptations or extensions to the next larger product are also possible without great effort. The selection and change between layers to be separated in the Process is carried out exclusively by software, without the need for any mechanical modification or adjustment of the celluveyor.

The celluveyor handles the entire separation and sorting process fully automatically. The celluveyor communicates with the higher-level control system via a simple Profinet interface. Our celluveyor DEPAL systems are equipped with our image processing system and artificial intelligence.

In summary, our cv.DEPAL offers you automated layer separation during depalletizing and thus enormous advantages. Especially when the system is to sort objects onto different conveyor lines in a process-reliable manner and on a small surface area.

cv.DEPAL

cv.GO

Company

Alexander Wyluda

Sales

Is the cv.DEPAL the machine you’ve always been looking for? There are still questions open?