cellumation at the LogiMAT in Stuttgart 19. – 21. March 2024

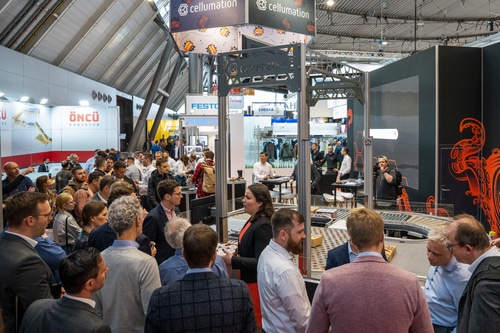

Visit us and get to know our cv.CROSSDOCK, which recently received the “VDI Innovation Award Logistics” at the Material Flow Congress 2024. Experience one-model-hardware as it’s best at LogiMAT 2024. cellumation presents itself even bigger and more innovative under the motto “every revolution starts with a cell”.

Hall 3, Stand 3A19

What you can expect at our stand

Application for best product

Get to know the cv.CROSSDOCK! We have applied with our product innovation for the award: Best Product Logimat, in the category ‘Picking, Conveying, Lifting, Storage Technology’.

The cv.CROSSDOCK offers unprecedented flexibility, allowing sorting from any number of inputs to any number of outputs. From small distributors with one input and two outputs (cv.CROSSDOCK 1:2) to medium-sized sorting systems with three or four inputs to six or twelve outputs (cv.CROSSDOCK 3:6 and 4:12) to sequencers with 34 bidirectional inputs and outputs (cv.CROSSDOCK 34:34) – there are no limits. At the same time, all objects are ideally aligned and oriented. The automated singulator utilizes modular celluveyor technology combined with an intelligent vision system.

The success story of the cv.CROSSDOCK began in 2020 at DHL in Greven, where it replaced an outdated system consisting of a merge and a pneumatic switch sorter. With the previous solution, there were frequent failures due to object jams when merging two material flows multiple times a day. An employee had to use a broom to clear the jams over two meters high in the previous solution. The system was outdated, consumed too much energy, and caused additional technical failures. After an incredibly fast integration in just 1.5 days, it not only increased throughput by over 40% but also improved the energy balance of the system and completely eliminated unplanned downtime. This led to amortization in less than a year. The system has proven to be an extremely effective solution, creating measurable value for the customer.

One cv.CROSSDOCK in operation: DHL Greven

Even more celluveyor

This year, you can discover a celluveyor not only at our booth!

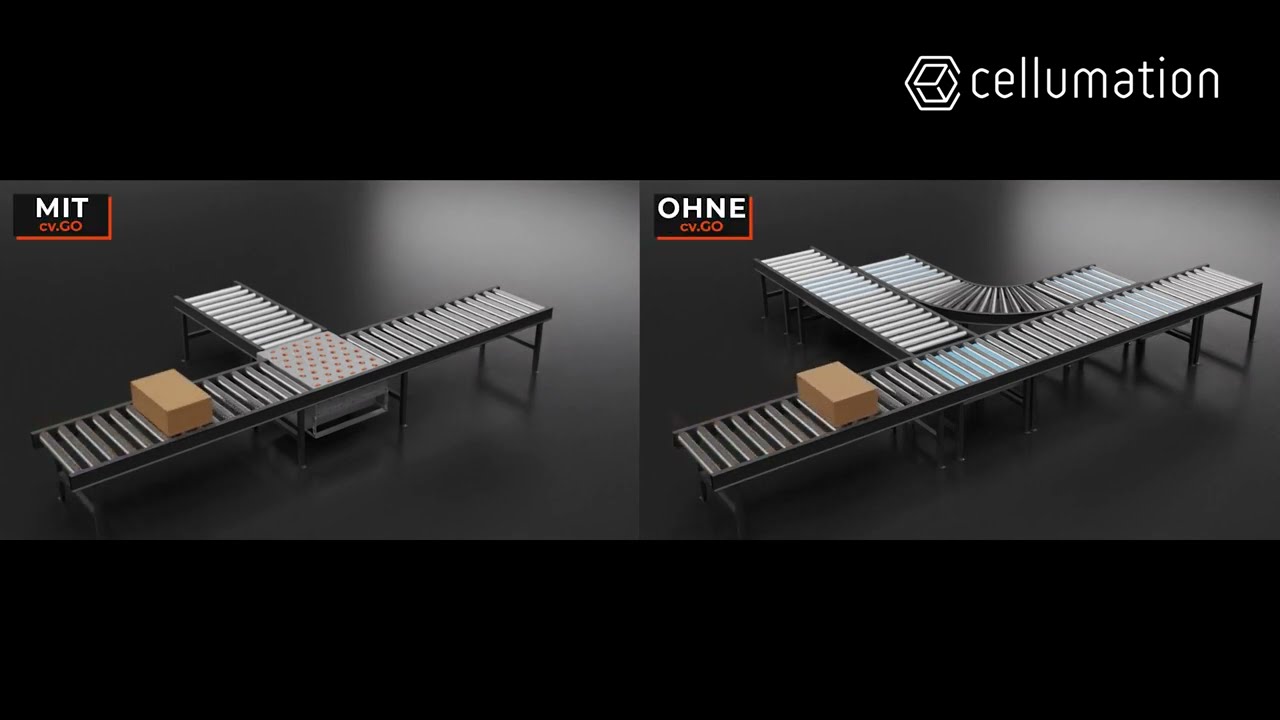

Our all-rounder, the cv.GO, is also in use at our partner TAF Industriesystems at Stand: 7B77 in Hall 7 or at ETF-Solutions at Stand 5F27 in Hall 5.

Our experts for intelligent, efficient material flows

We have celluveyor and our experts for intelligent, efficient material flows in tow: Plan directly on-site with our sales team on your projects, discuss possible flexibilization options with our software team, find new markets with our marketing team, brainstorm new ideas with our product team, talk to our founders and CEOs about partnerships, and with our service team about the simplicity and speed of integration.

Our events at LogiMAT

Tech‘n‘Talk with “Bier ab Vier”

Once again this year, we want to engage in conversation with you. Every day of the fair, we offer our own beer starting at four. Come by, join the conversation, and let’s exchange impressions of the day.

Mixed doubles

IMWL x Logistics Summit are hosting the most athletic after-show party after the first day of the fair. Do you want to be there?

Buy your ticket here: https://logisticssummit.de/gemischtes-doppel

IWML Guided Tour

The logistics podcast in the German-speaking world is once again curating the most exciting technologies and most beautiful stands this year. The logistics experts guide you through the LogiMAT jungle and put you directly in touch with the exhibitors.

Please research the website for more information: https://irgendwas-mit-logistik.de

Let’s talk!

The LogiMAT is the perfect opportunity to talk to us and see our technology live.