Air cargo handling:

Challenges and solutions for

air cargo

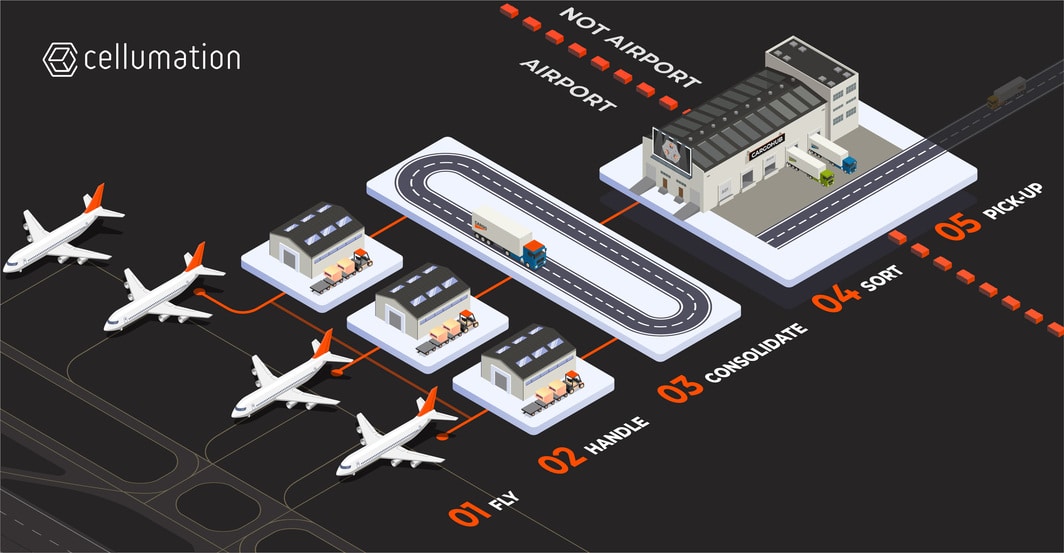

In the air cargo industry, air cargo handling represents an essential part of logistics. It is the binding link in the airport area to transfer air cargo from aircraft to truck, and also from truck to aircraft.

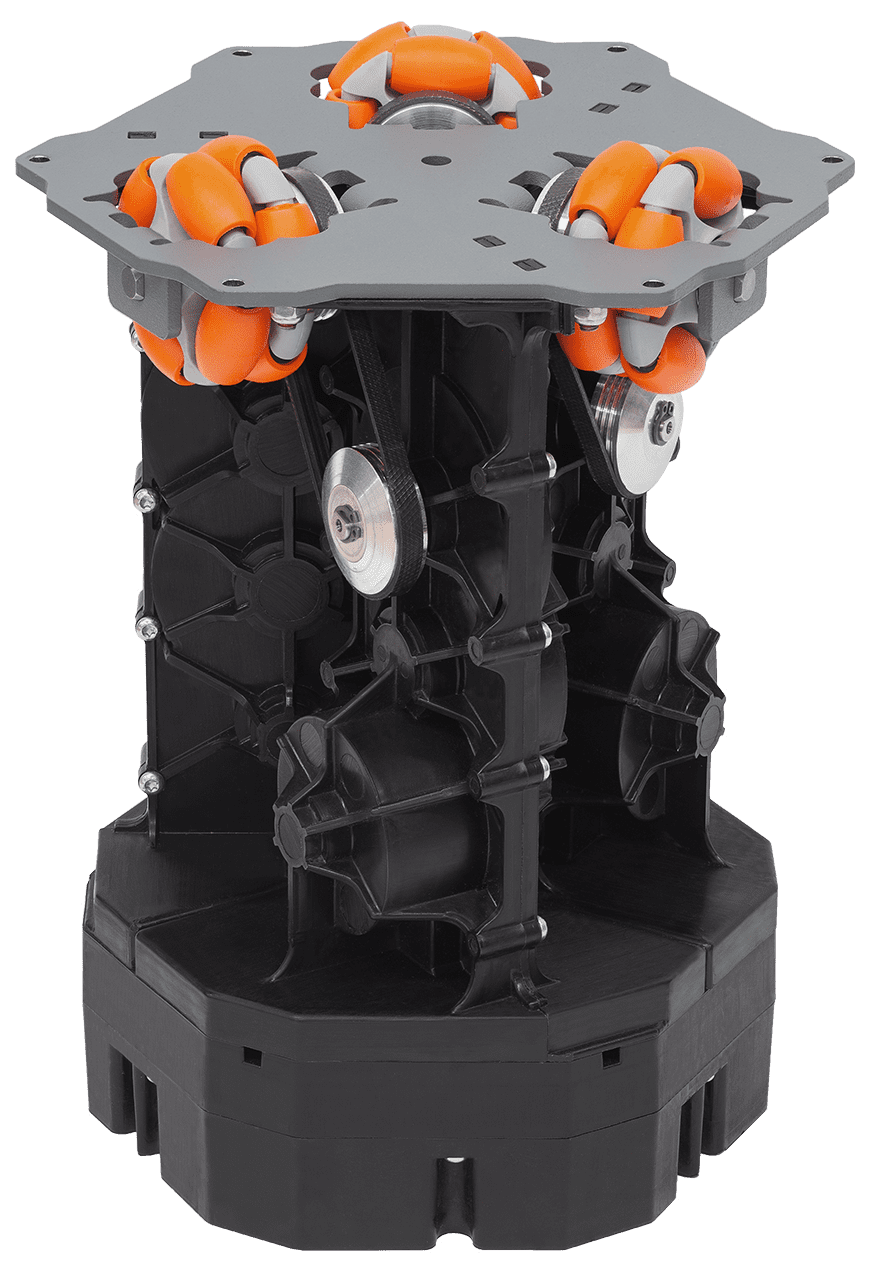

celluveyor and air cargo

Faster, more efficient and cheaper

Air freight is the fastest way to transport goods over long distances – but, it is also the most expensive. Air freight carries about 0.05% of all goods shipped worldwide. However, looking at this from a different angle, air freight transports about 35% of the value of all goods shipped. In this context, the implementation of celluveyor technology offers significant optimization opportunities for numerous processes, including some that are currently performed manually.

Our motivation

Little automation in air freight

Some of the logistics technology used in the air freight sector is outdated or has processes that are not optimally automated when compared with the current technological status in the rest of the intralogistics sector. Most of the work is still done manually. The reason for this is that the packages of air freight shipments are not always uniform. From very large packages, such as pianos, to very small packages, the size of a letter, everything is involved in air freight transport. Until now, this has made automation very difficult.

Frequent manual sorting

But the pressure is mounting: Manual sorting is very labor-intensive and tends to lead to errors and failures in the supply chain. This is exactly what causes delays and congestion, which are major problems for the industry, as the delivery of goods are dependent on tight schedules, such as the airplanes, and they cannot wait for the baggage if there are failures in the supply chain beforehand. In addition, the shortage of skilled workers continues to rise, adding to the urgency of finding alternatives. This is where a flexible and intelligent solution is needed.

E-COMMERCE AS A DRIVER

Satisfying customer expectations

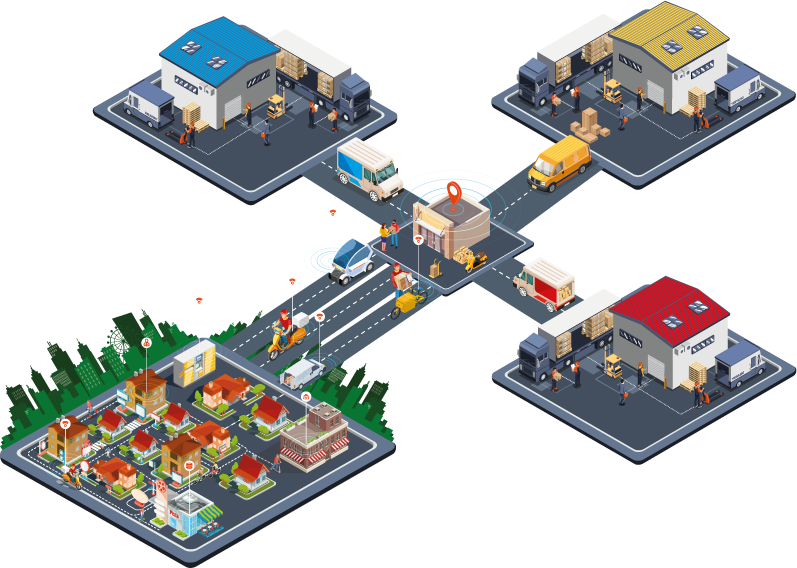

Online commerce was, during the COVID-19 crisis, a key driver for air cargo and has remained so thereafter. Accelerated by changing consumer behavior, global online trade is estimated at $5 trillion, and 80% of cross-border online trade is transported by air, accounting for 22% of total air cargo volume in 2022. This poses two major challenges for air cargo.

First, e-commerce traffic is largely loose freight. Also, the average segmentation per AWB (airway bill) is much higher compared to general cargo. This creates additional handling costs, especially for storage and sorting. While forwarders achieve an average operating profit margin of about 8%, the margin for loose freight drops to 1-5%. In addition, the errors caused by manual handling result in enormous costs.

The second factor is customer expectations. Delivery times are among the three “extremely important” factors for a painless customer experience. The already well-established demand for same-day or next-day delivery is transferring to cross-border traffic, making all air cargo players part of the express supply chain.

The combination of growing demand (due to e-commerce), a shortage of skills, and ineffective technology creates a massive problem. Ways must be found to sort and distribute more freight faster.

Automated sorting

cellumation technology as gamechanger

The patented celluveyor technology enables powerful automation in the smallest possible space: an important prerequisite for logistics in the air freight industry.

Application examples demonstrate the advantages of cellumation’s technology.

Example Aircargo Hub:

Reconsolidation & sorting according to ground handling service providers in a cargo hub (transition from ground handling service providers to trucks). In the first step, a typical package lands at the destination airport by airplane. Then, in a second step, it arrives at a ground handler and then continues to the consignee by a freight forwarder. Currently, there are several ground handlers and several forwarders at each airport, each of which has to pick up the parcels from the ground handlers. The problem with this is the high transaction costs that arise because freight forwarders have to pick up the packages from each individual ground handler. This leads to unnecessary routes and causes delays.

Solution for Aircargo Hubs:

Benefits through automation, using the last mile as an example:

- No unnecessary trips (trucks don’t have to go to multiple final handlers. They only need to drive to the sorting point)

- Time savings (1. Due to centralized and fast sorting; 2. No more truck congestion in front of ground handlers)

- Space saving

- Error reduction

- Added value through consolidation

Key Facts:

- The industry is struggling with the growth of e-commerce.

- Saving up to $0.50/package handling cost

- Reduction in turnaround time

- Reducing airport traffic

- Same-day cross-border delivery becomes a reality

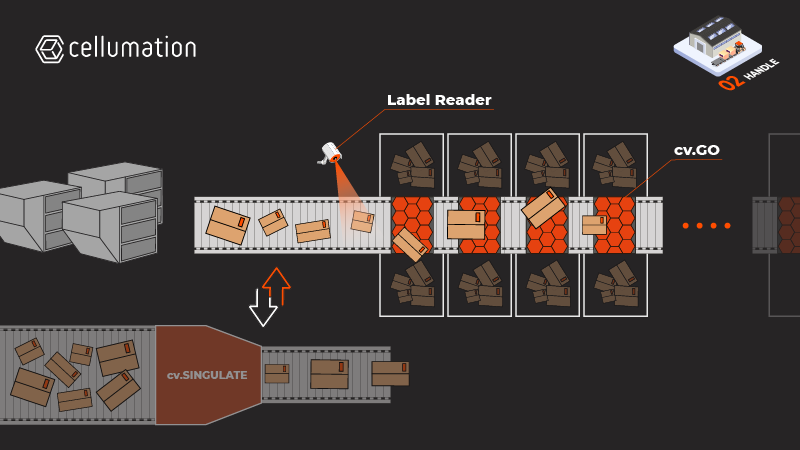

Air Cargo Terminal Sortation:

Reconsolidation & sorting at terminal/ground handlers themselves (sorting in ground handler hangars).

Sorting of ULDs (Unit Load Device) with multiple units based on (main and house) air waybills.

Automation benefits:

- Internal processes are made more efficient

- Space savings for ground handling service providers

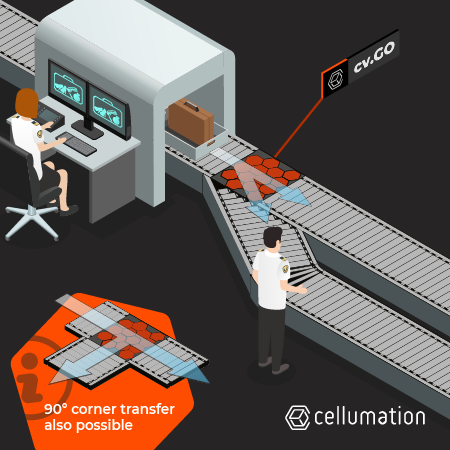

Curve ejection according to X-Ray for package handling (In the hall area for passengers and baggage):

Ejection of baggage (90°/30°) depending on the decision of an X-Ray scanner operator.

Advantages through automation:

- Baggage no longer gets jammed during ejection (if it currently works mechanically) no more jams/interruptions

- Personel is saved (if it is currently done manually)

The celluveyor technology offers many possibilities to significantly optimize existing processes in air cargo handling.

Let’s talk!

Let’s talk about how we can achieve the highest performance in your material handling system with our powerful celluveyor technology.

Tel. +49 (0) 421 331135 0

Fax +49 (0) 421 33 11 35 99

Mail info@cellumation.com

Kleiner Ort 7

28357 Bremen

Germany

Legal notice & Jobs