celluveyor DEPAL:

The compact & powerful layer separation system for depalletizing

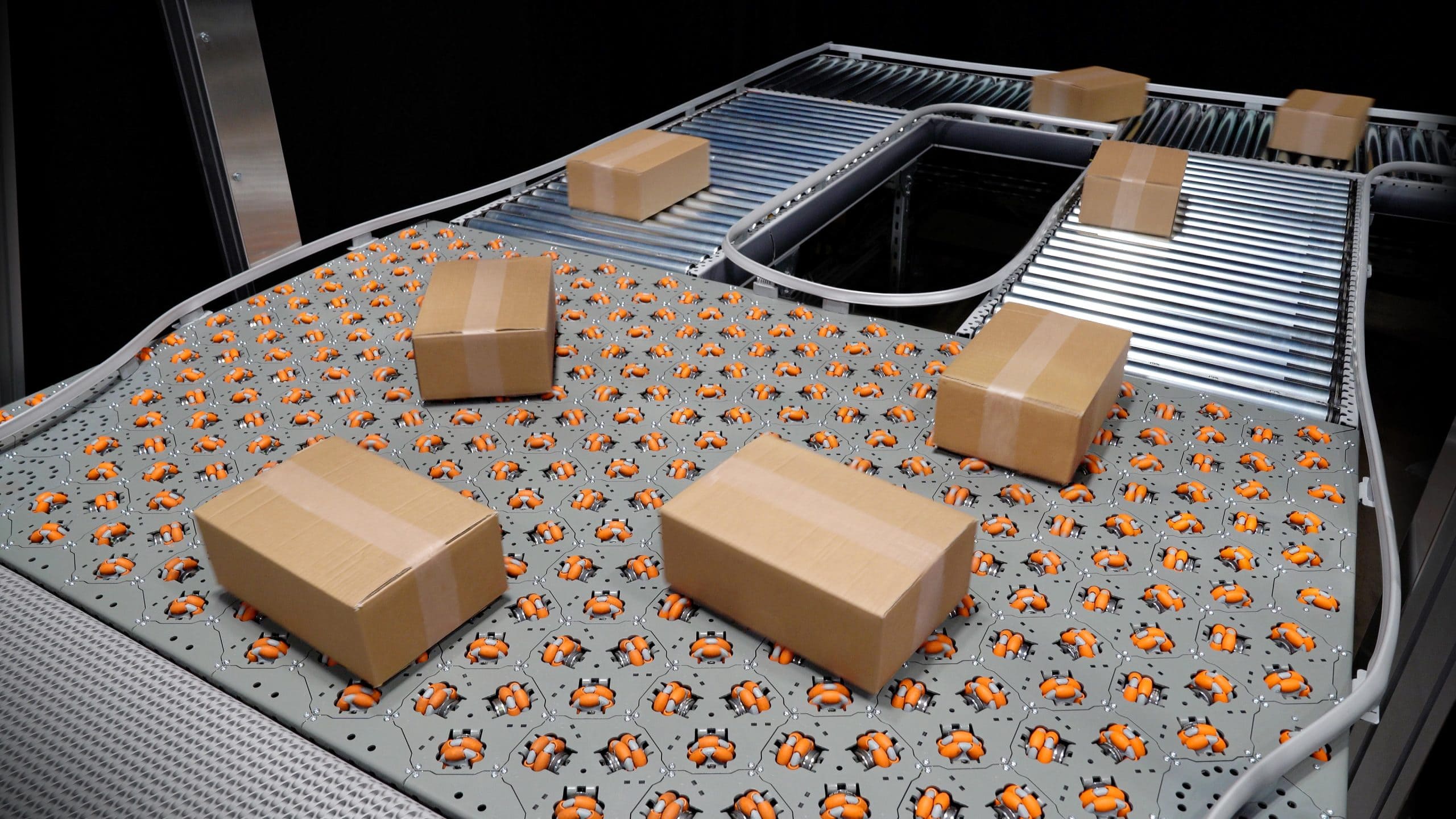

The celluveyor DEPAL is used when pallet layers need to be separated and aligned in the flow of goods. Its specialty is the processing of any pallet types, layer patterns and product categories without prior knowledge.

Benefits of the celluveyor DEPAL

Powerful

The cv.DEPAL processes up to 450 palletlayers per hour or 5200 pph and feeds them to up to three different outputs. During the process, the objects are rotated and orientated by the force of the wheels only to protect the products and their packaging.

Smart

Our vision system records all relevant information in real time. For this reason, no teach-in or calibration is required for new layer layouts. Thus, other layouts do not require a changeover period.

Compact

Software-based conveyor technology and intelligent cells make it possible: the cv.DEPAL descrambles layers on less than 3 m².

The celluveyor can singulate different pallet layers on less than 3 sqm, orientate them and direct them to the correct ongoing conveyor lanes.

Without any manual support, bumpers or stops. The cv.DEPAL integrates seamlessly with adjacent conveyor systems. It generates the information needed to calculate the paths of the products to be singulated by its intelligent vision system itself. Therefore, it can automatically process different layer patterns without changeover times. This increases productivity through less downtime.

Space saving

Classic systems for layer separation can take up to 60 sqm of space, our omnidirectional celluveyor solution, such as the cv.DEPAL, requires less than 3 sqm to separate layers with flat substrates. The singulated objects can be distributed to up to three outputs for subsequent processing according to individual customer requirements. The hexagonal robot cells are designed for use in a wide variety of areas – the hardware of the cell always remains the same, while the intelligent software controls and defines the function.

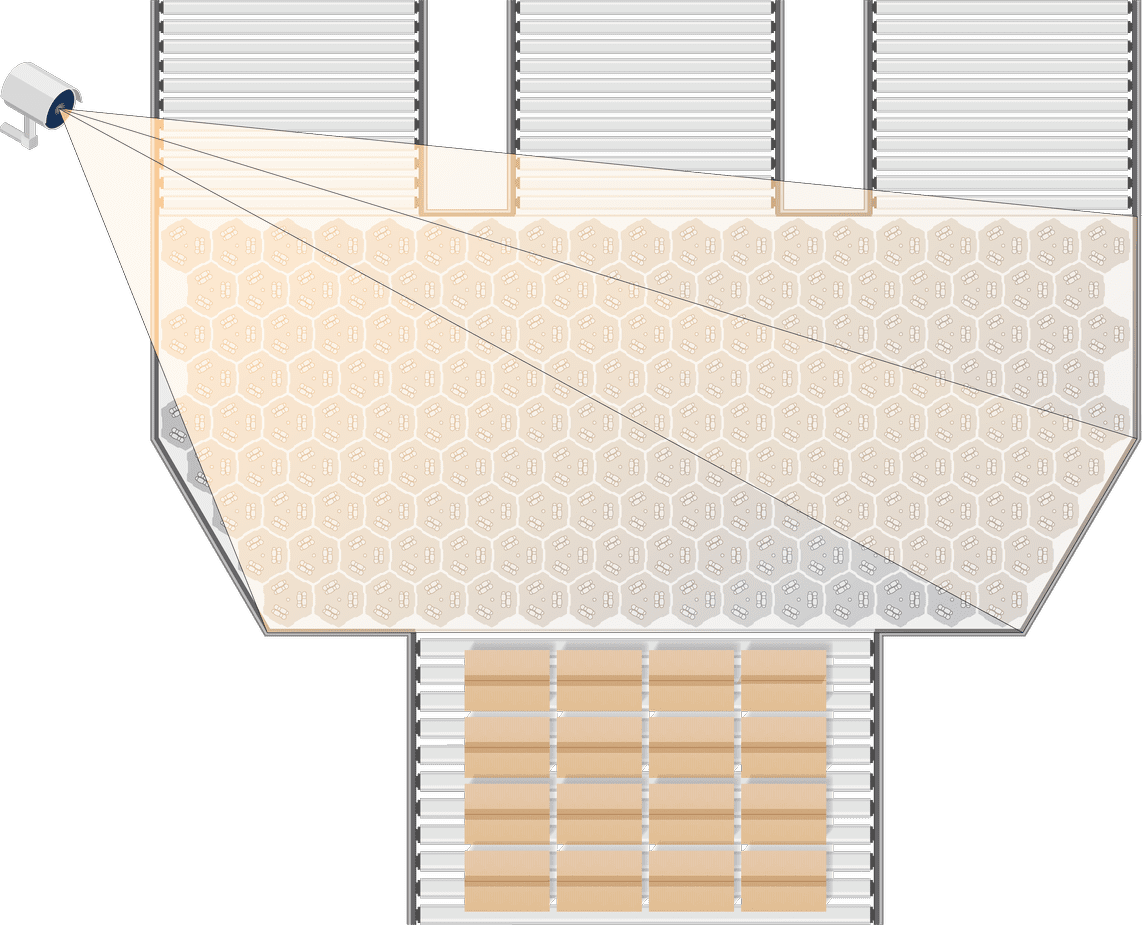

The DEPAL’s intelligence is generated by a vision system and optionally by an identification system.

They collect real-time-data, which is then converted into action instructions for the cells. For this reason, even imperfectly aligned pallet layers can be recognized and processed easily. On the celluveyor, the passengers (cartons / parcels / goods) are tracked with 3D cameras. If something needs to be changed, our vision system detects this in real time and corrects the position so that the celluveyor takes the passenger to the correct destination.

Our technology consists of hexagonal robot cells that can be easily combined to form different layouts. In this way, we can produce any surface from a single component. The software controls the movements. The integration of the system is also simple: we use standard industrial interfaces and have short installation times. A maintenance process takes less than 5 minutes to complete: you need a screwdriver, loosen seven screws, remove the cell, insert the next one, press the start button and the system is ready for use again.

Simplicity is the key.

Layers per Hour

Square meter

Functionality & skills of the cv.DEPAL

An infeed conveyor or a layer gripper transports the layer (in any orientation) onto the celluveyor. The maximum width is 1,350 mm.

In the transition zone, our vision system automatically identifies the objects. No additional information is needed. Each individual path is calculated at this stage.

The packages move towards the predetermined exit and are aligned on the way. The movements on the celluveyor are tracked by the vision system. Unusual movements are detected and corrected in real time.

In the standard configuration there is one output. This can be extended to up to two outputs.

With us, the robots are upside down: the cells create an intelligent driving base on which independently driven omnidirectional wheels guide the packages along the right path. The smallest conveyable object is 150mm x 150 mm.

The vision system is the eye of the DEPAL. It detects the objects and passes the information on to the cells.

Singulation of objects

The celluveyor DEPAL singulates and followingly orients the objects of layers of any shape, size and pattern. This allows them to be automatically processed in your system.

Sorting to 3 outputs

The descrambled objects can be sorted to up to 3 outputs for subsequent processing according to the desired customer logic.

Camera Feedback

A vision system comprising several 3D cameras detects the transported objects and provides permanent feedback on their position . In this way, deviations from the expected position can be corrected directly.

Flexible range of objects

The celluveyor DEPAL can transport all objects with a flat bottom surface (packages, trays, KLTs) and a minimum size of 150mm x 150mm.

No PLC programming necessary

The celluveyor takes over the complete descrambling and sorting process fully automatically. A simple interface (I/Os, Ethernet, etc.) connects the celluveyor to the higher-level control system.

Small footprint and low noise level

The celluveyor DEPAL singulates and sorts objects in a space-saving manner on less than 3 sqm. It is a toothless tiger that can be kept outside a cage and operated without hearing protection due to low noise emissions of <70dB.

The new cv.DEPAL system

The cv.DEPAL in applications

Industry & Production

In production, goods stored on pallets are frequently required to be further processed and for this reason to be singulated or repacked. Currently, descrambling either takes up a lot of space or requires a lot of muscle power. The cv.DEPAL supports these processes without muscle power and on less than 3 sqm.

Warehouses & distribution centres (e.g. e-commerce or supermarkets)

In distribution centres or warehouses, many products are delivered on pallets and stored individually. The cv.DEPAL helps precisely at these interfaces, separating the goods and placing them on the correct track so that they can easily find their storage location.

cv.GO

Products

Applications

Alexander Wyluda

Sales

The cv.DEPAL would be perfect for your application? There are still questions open?