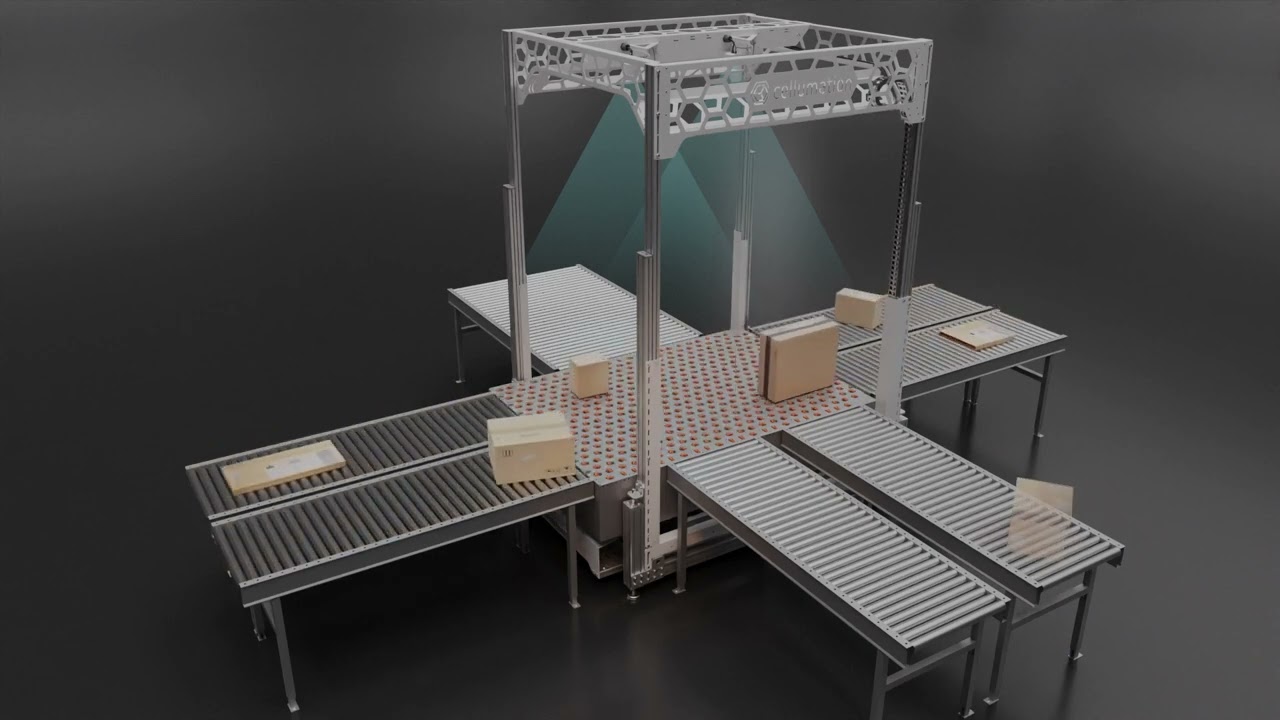

cv.CROSSDOCK:

Sort objects from different numbers of inputs to different numbers of outputs

The cv.CROSSDOCK replaces manual processes and simplifies complicated linkages in the material flow.

celluveyor CROSSDOCK

The 360° freedom of movement

Due to the cv.CROSSDOCK there are no limits to creativity.

The Challenge

In every material flow, there comes a point where objects from different numbers of lines must be sorted or distributed to various lines. This process is often performed either manually or by complex interlinking of converters, switches, pushers and more – in summary: by complicated component chains

The Solution

The cv.CROSSDOCK enables objects to move seamlessly from any number of inputs to any number of outputs. Its modular and flexible design allows for the creation of nodes (crossings or sorters), which can pick up and transfer objects in any direction. When an object enters, the cv.CROSSDOCK is informed to which exit the object should be moved.

The 360° freedom of movement, in combination with the individual tracking of the objects on the surface ensures quick and collision-free transportation of objects to the desired destination. Separated wheel control allows for independent (in different directions) object movement on a little surface creating a complex objects ballet. Typically, the cv.CROSSDOCK can act as a classic crossover (switch) in a 2:2 configuration, distributing material flows from two inputs to two outputs. For even greater flexibility, the novel combinations are possible, such as 3 inputs to 5 outputs. 34 bidirectional inputs/outputs or even a chaotic cris-cross resembling a traffic intersection. Traditionally, these process steps are often performed manually, with a lot of physical effort, or solved in a complicated way by complex component chains. With the cv.CROSSDOCK there are no limits to creativity.

The cv.CROSSDOCK is . . .

MORE COMPACT AND COST-EFFECTIVE

system layouts through flexible design and individual object tracking

FIT FOR RETROFIT

flexibility & performance increase when retrofitting an existing system.

FUTURE-PROOF SCALABLE

of celluveyor technology

SIGNIFICANTLY SPACE SAVING

through independent and simultaneous object movements.

VERSATILE

of layout conception

EASY TO MAINTAIN

and replacement part mangement due to the modular design based on celluveyor cells

TBA

FOOTPRINT

TBA

MAX. THROUGHPUT

TBA

SPEED

TBA

SOUND LEVEL

Let’s talk!

Let’s talk about how we can achieve the highest performance in your material handling system with our powerful celluveyor technology.

Tel. +49 (0) 421 331135 0

Fax +49 (0) 421 33 11 35 99

Mail info@cellumation.com

Kleiner Ort 7

28357 Bremen

Germany

Legal notice & Jobs