cv.PAL:

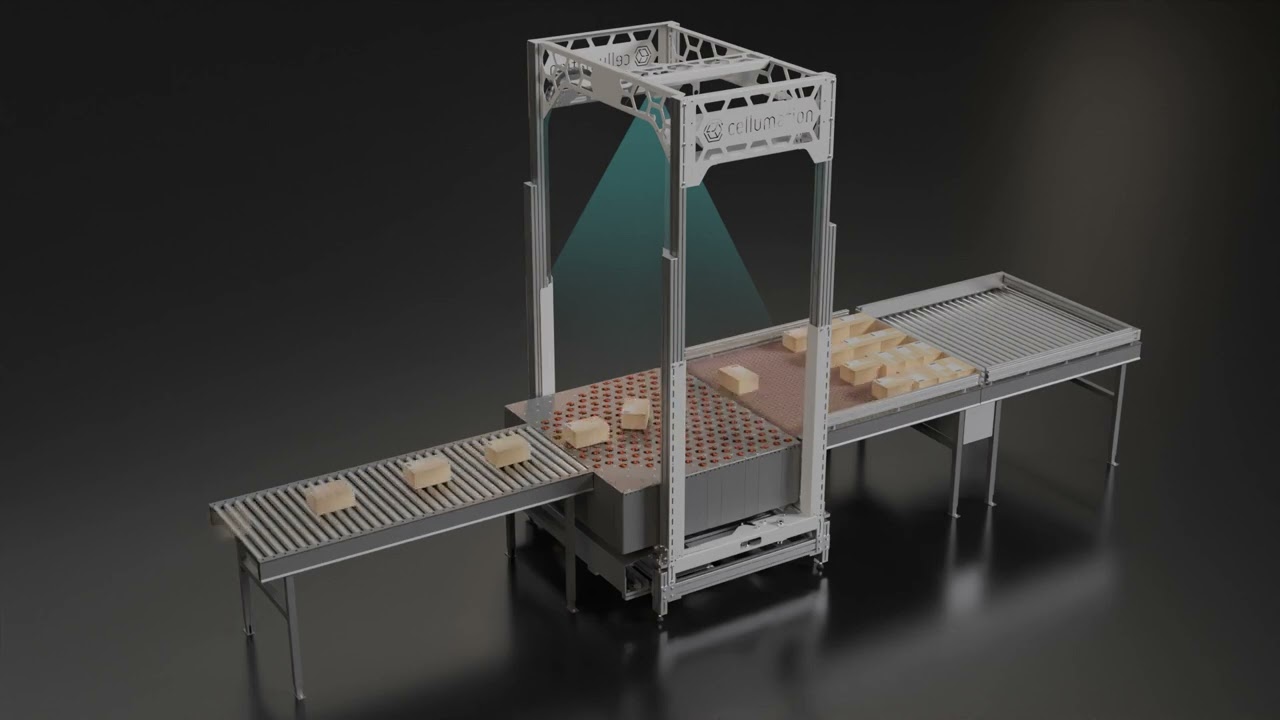

Forming pallet layers where space is limited.

Different layer patterns are simply brought into shape. The automation of a partly still manual process by the cv.PAL.

celluveyor PAL

Efficient formation of precise and different layer patterns

The cv.PAL can compensate for packages with errors in positioning and orientation, so that perfect layers can still be formed.

The Challenge

To be easily moved from one logistics center to another or from one produc – tion facility to the next, objects are stacked on pallets worldwide. This process is often carried out manually. Automatic solutions either require large areas or only achieve lower performance. But we see it more and more frequently: In production, ever higher palletizing capacities are becoming necessary with ever smaller surface areas.

The Solution

The cv.PAL precisely and quickly forms different layer patterns from packages. It compensates for errors in positioning and even orientation ensuring perfect layers to be formed. These layers are then compacted and can be transferred to a pallet by a gripper arm robot, for example. In combination with an accu – mulation unit and a compactor, the cv.PAL-based unit forms layers so quickly that the gripper arm robot reaches its performance limits. The 3D vision system and the omnidirectional capabilities of the cv.PAL allow for the compensation of inaccuracies in the positioning, alignment and/or orienta – tion of the packages at the infeed, consistently creating perfect layers.

The cv.PAL is . . .

EASY FORMING

Of different layer patterns.

HIGHLY PERFORMANT

With minimal footprint.

SAVES TIME

No setup times when changing between layer patterns.

SIMPLY CONTROLLABLE

Intuitive user interface for quick definition of layers.

FLEXIBLE

Suitable for almost any layer pattern and pallet size (Euro, CHEP, Australian, etc.)

EASY TO MAINTAIN

And spare parts management due to modular design based on celluveyor cells.

from 1.5 m²

FOOTPRINT

TBA

MAX. THROUGHPUT

TBA

SPEED

< 70 dB (A)

SOUND LEVEL

Let’s talk!

Let’s talk about how we can achieve the highest performance in your material handling system with our powerful celluveyor technology.

Tel. +49 (0) 421 331135 0

Fax +49 (0) 421 33 11 35 99

Mail info@cellumation.com

Kleiner Ort 7

28357 Bremen

Germany

Quick Links

Rechtliches & Jobs