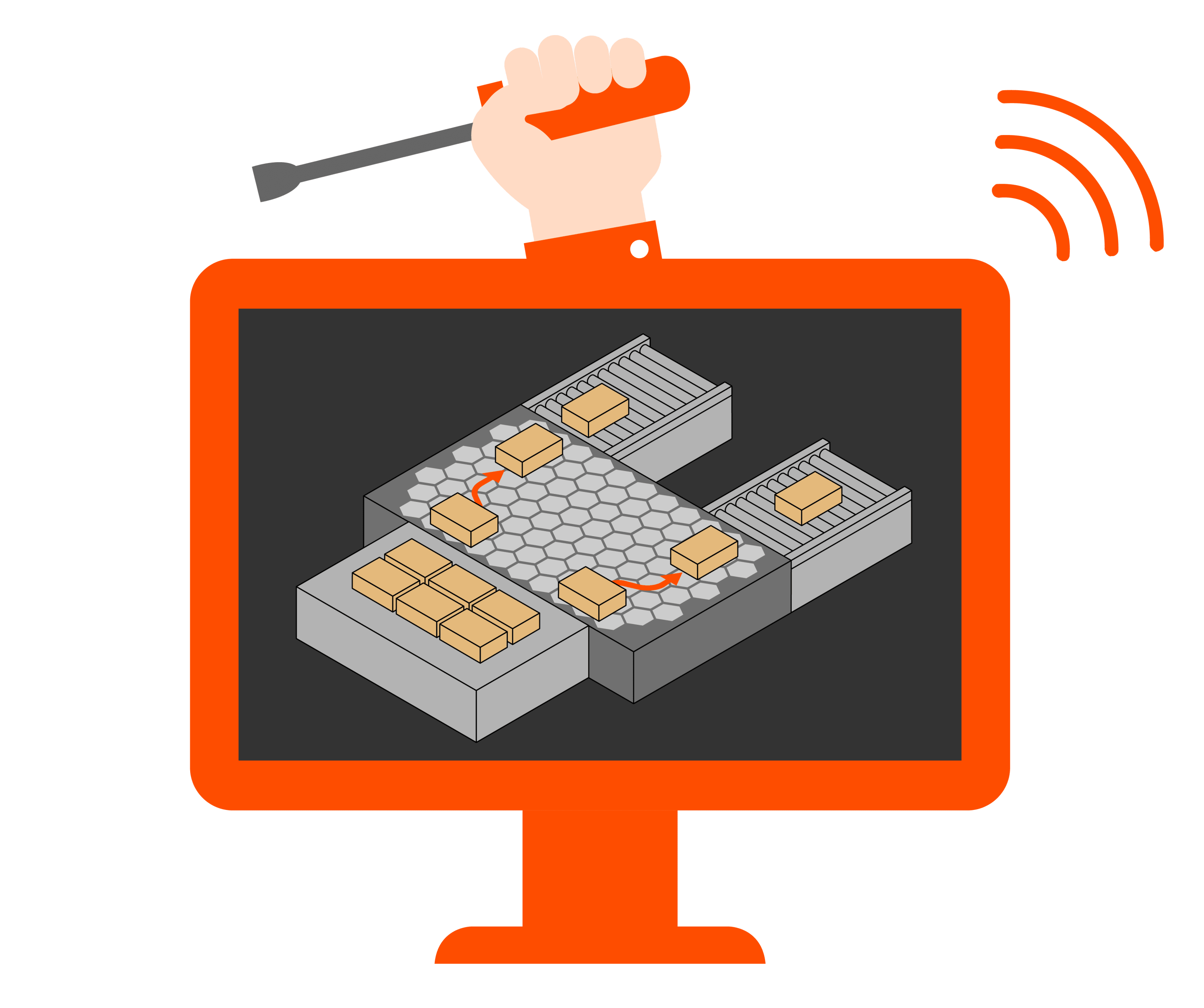

Automatic sorting and sequencing

on a celluveyor XXL

In this use case, the Spanish company Verdnatura uses the celluveyor cv.CROSSDOCK to automate their processes. In order to optimally arrange shipping pallets, Verdnatura uses the celluveyor to sort and intelligently place objects in the correct order depending on the pallet pattern.

The players

Verdnatura Levante SL: User

Verdnatura is the leading company for flower and plant shipping in Spain. The celluveyor is part of a new installation for commissioning, packaging and automatic shipping preparation of flowers and plants in the town of Algemesí near Valencia, Spain. The goal of the project was to optimize the preparation of the shipping process.

VCON: Implementing partner

Vector Conveyors is a Spanish company and a partner of cellumation from the very beginning. Founded in 2017, VCON offers comprehensive automation services. High customer orientation and tailored solutions are their focal point: that‘s why VCON works with the newest and most advanced technology.

cellumation: Manufacturer

Our goal: in the future, every package delivered worldwide will have touched a celluveyor cell. For this reason, we build software-driven conveyor technology for complex applications. The hardware consists of one main component: the celluveyor cell. This gives us unlimited flexibility in layout, easy maintenance and fast assembly.

The players

Verdnatura Levante SL: User

Verdnatura is the leading company for flower and plant shipping in Spain. The celluveyor is part of a new installation for commissioning, packaging and automatic shipping preparation of flowers and plants in the town of Algemesí near Valencia, Spain. The goal of the project was to optimize the preparation of the shipping process.

VCON: Implementing partner

Vector Conveyor is a Spanish company and a partner of cellumation from the very beginning. Founded in 2017, VCON offers comprehensive automation services. High customer orientation and tailored solutions are their focal point: that‘s why VCON works with the newest and most advanced technology.

cellumation: Manufacturer

Our goal: in the future, every package delivered worldwide will have touched a celluveyor cell. For this reason, we build software-driven conveyor technology for complex applications. The hardware consists of one main component: the celluveyor cell. This gives us unlimited flexibility in layout, easy maintenance and fast assembly.

cv.CROSSDOCK in action

In this application, complex motion sequences are brought together with just one system.

- 11 meters long

- 428 cells

- 10 x 3D-Vision-System cameras

The cv.CROSSDOCK is infinitely expandable, due to its modular design.

An outstanding celluveyor XXL

In March 2021, Verdnatura moved into a new warehouse with the intention of automating their operation. The celluveyor SORT is the centre piece of the pallet commissioning system. With a length of over 11 meters, 428 cells, 10 synchronized cameras and 34 bidirectional buffers, the system sorts and sequences all orders for optimal palletizing. Each output is for one recipient.

For more flexibility, every buffer can be repurposed as an inbound for special orders or as an outbound for an extra palletizing station. This guarantees optimal order processing at any order volume, but specially in peak seasons.

Automated

Sequencing & Sorting

The sequencing process is complex and requires an intelligent solution. Two challenges have to be overcome: first, the objects must be assigned to the correct recipient. Secondly, to ensure that a pallet is packed in the ideal way, the objects must be placed in the correct packing sequence. It makes sense to place the heavy objects first on a pallet. Therefore, they must arrive first at the recipient’s output, followed by the lighter objects. This is the only way to ensure that objects are not damaged during shipping and arrive at the recipient in good condition.

For this reason, the movements of the cv.CROSSDOCK resemble a ballet: lighter objects exit their designated output, park themselves on another buffer conveyor and the heavier objects slide by into the designated output. This process is fully automated and happens as if by magic, until all objects are arranged in the right order and in their correct designated output. An intelligent control system ensures that the objects are moved automatically in the most efficient way. In the process, new objects are added throughout the day and are temporarily stored on the conveyor belts. This process continues during the entire shift.

The cv.CROSSDOCK application resembles a huge, complex Tetris game in a real-life application. The celluveyor is the champion of the game: during an entire shift objects will be sequenced and sorted reliably.

Closely lined up roller conveyors

Intelligent cells move the packages precisely to the specific roller conveyor track

The cv.CROSSDOCK has enabled us to break out of the shackles of traditional conveyor technology. It provides us with the reliability and flexibility we need to pack goods of different sizes and weights in a way that is gentle on the objects. At the same time, the cellumation team has created a superlative robot with this machine: over 400 celluveyor cells now simplify our everyday work.

Rethinking the logistics process:

“Person-to-goods“ order picking becomes “Goods-to-person” order picking

Many shipping centers are still based on the supermarket principle today: A person walks through the aisles with a trolley and gathers the products for an order.

These are then packed and shipped. This process is based on the principle: person-to-goods picking.

For higher picking performance, the principle is reversed in modern shipping centers: automated or semi-automated racking and retrieval systems bring the goods directly to the individual.

This person packs the shipping package directly on the spot and therefore saves walking time.

At the same time, the range of articles is increased, and the error rate is reduced, because an intelligent system brings the right goods to the right order.

Picking workstations also enable greater ergonomics for employees, because lifting and lowering movements can be carried out at the ideal height.

Verdnatura has recognized the advantages of such a system and reversed the principle in their new warehouse. With the celluveyor CROSSDOCK and complementing traditional conveyor technology from the company Vector Conveyors a great gain in efficiency is achieved.

One advantage of the modular celluveyor conveyor system is its unlimited scalability. The individual cells are able to recognize their neighbors and work together as a team. The movements of the objects on the cell surface are controlled by a vision system. Various 3D cameras track the movements on the celluveyor and an intelligent software transforms this information into movement commands for the individual cells or wheels. If a box would move away of the planed path, a correction is performed. This ensures that objects always reach the right destination without collisions. Information on target outputs of the objects is provided by a programmable logic controller (PLC).

One special challenge of this use case is the large height of the objects filled with plants or small trees combined with a relatively small conveying surface. Thanks to the object-friendly movement by the celluveyor, the system can also move these objects without any problems. It is important that the center of gravity of the object is in lower third of the object.

Remote maintenance and spare parts storage of the cv.CROSSDOCK

The celluveyor is brought to life by its intelligent software. Therefore, remote maintenance from Bremen or the remote implementation of new features is possible. Since the commissioning of the cv.CROSSDOCK in 2021, Verdnatura has been growing 2-digit percent per year. Though improvements in the control algorithm, path planning and collision avoidance, cellumation installed several software updates that increased the performance 300 % without even touching the hardware or increasing travelling speeds of the boxes.

Nico Loibersbeck

Sales

Are you interested in exploring the possibilities of the celluveyor technology? Take the chance and make an exclusive appointment with us!

cv.DEPAL

Products

Company