celluveyor GO:

The intralogistics all-rounder

corner transfer unit, diverter and more

The celluveyor GO is an ideal system for intralogistics applications in the smallest of spaces. Individually assignable motion profiles, adapt to your requirements. This allows the cv.GO to be used as a corner conveyor, for example, but it can also divert, rotate objects and much more. The compact size in combination with the extensive possibilities find an application in many areas of logistics.

celluveyor GO

One product for many applications

The celluveyor GO is a variant of the celluveyor technology that works without a camera and is installed as an integratable module on the frame in the standard conveyor technology. With up to 16 individually configurable and combinable motion profiles, the cv.GO offers a wide range of application possibilities for a wide variety of applications. It is able to perform all applications in real time and individually for each package.

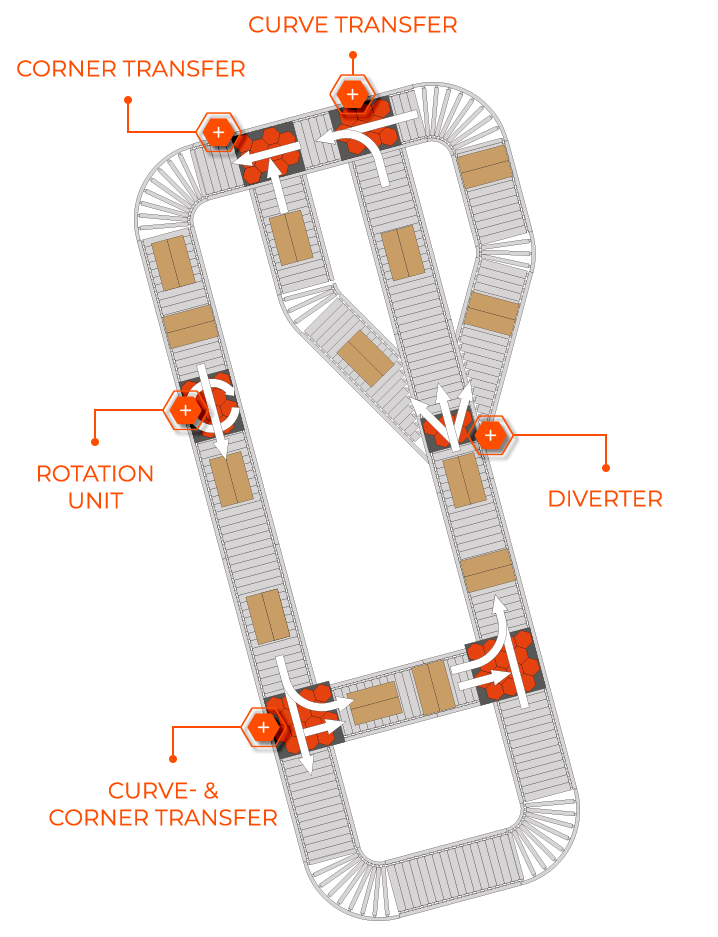

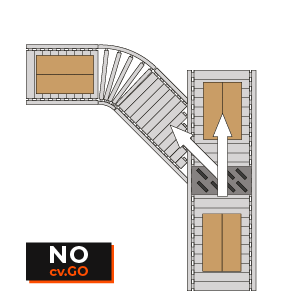

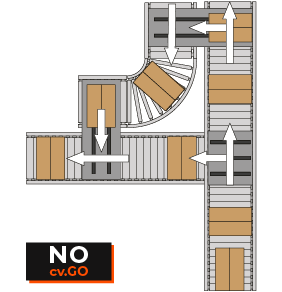

Corner transfer

A precise 90° corner transfer is no problem for the cv.GO.

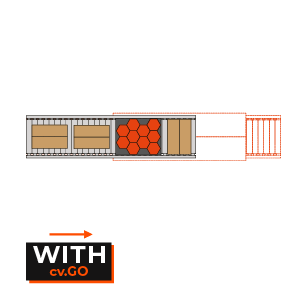

Rotation

Packages can be rotated individually and will be aligned directly to the side guide.

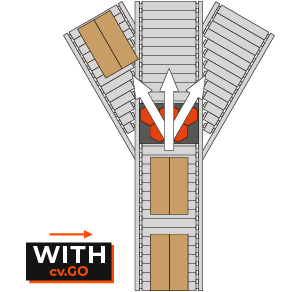

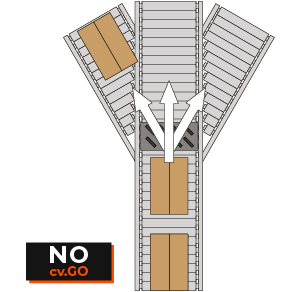

Diverter

The divert angle can be adjusted steplessly and individually.

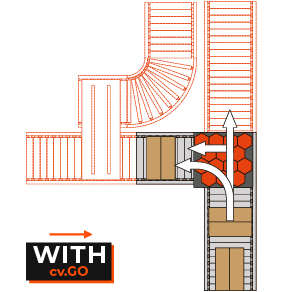

Curve transfer

More freedom in designing the overall layout. 90° curve – precise and fast.

The cv.GO is . . .

multi-functional

16 individually assignable memory slots allow absolute flexibility of movement.

powerful

The cv.GO conveys precisely, quickly and in all directions (from 0 to 360°) at 1.15 m/s.

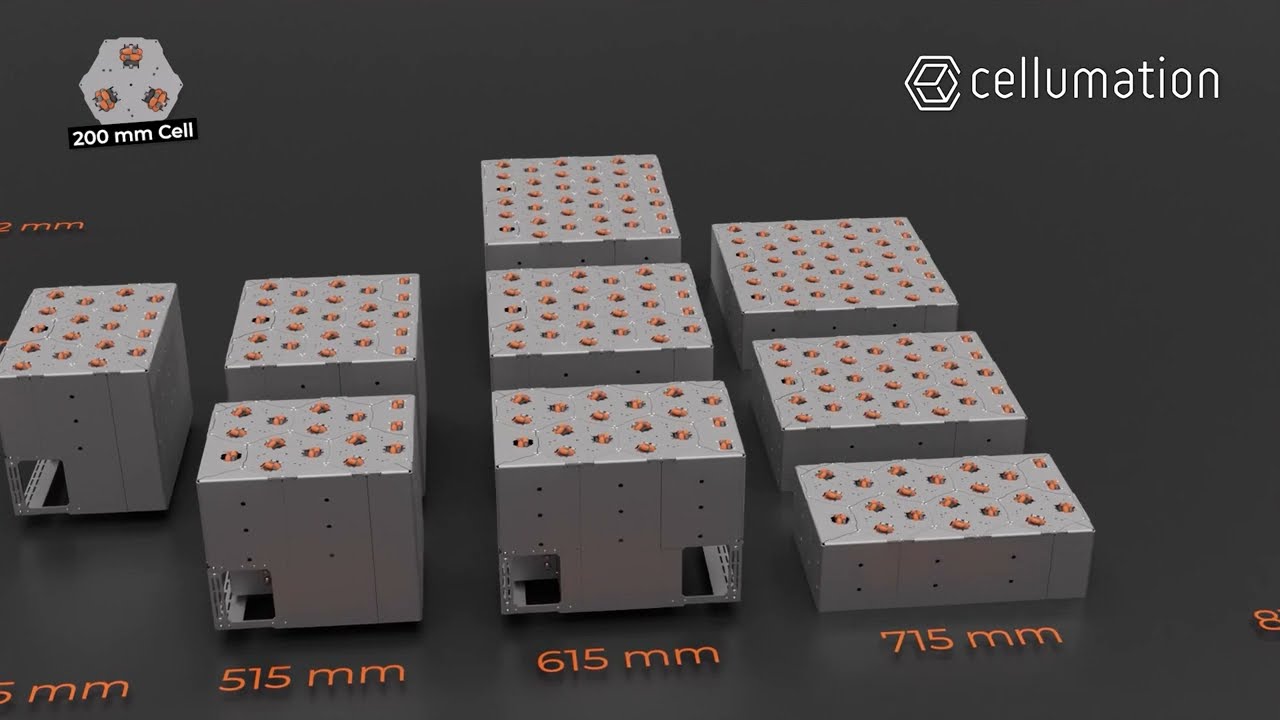

modular expandable

The size of the cv.GO is freely selectable. Depending on the size of the objects, the number of cells can be adjusted.

100% electrical

We never run out of air. The cv.GO only needs 48V and runs completely electrically.

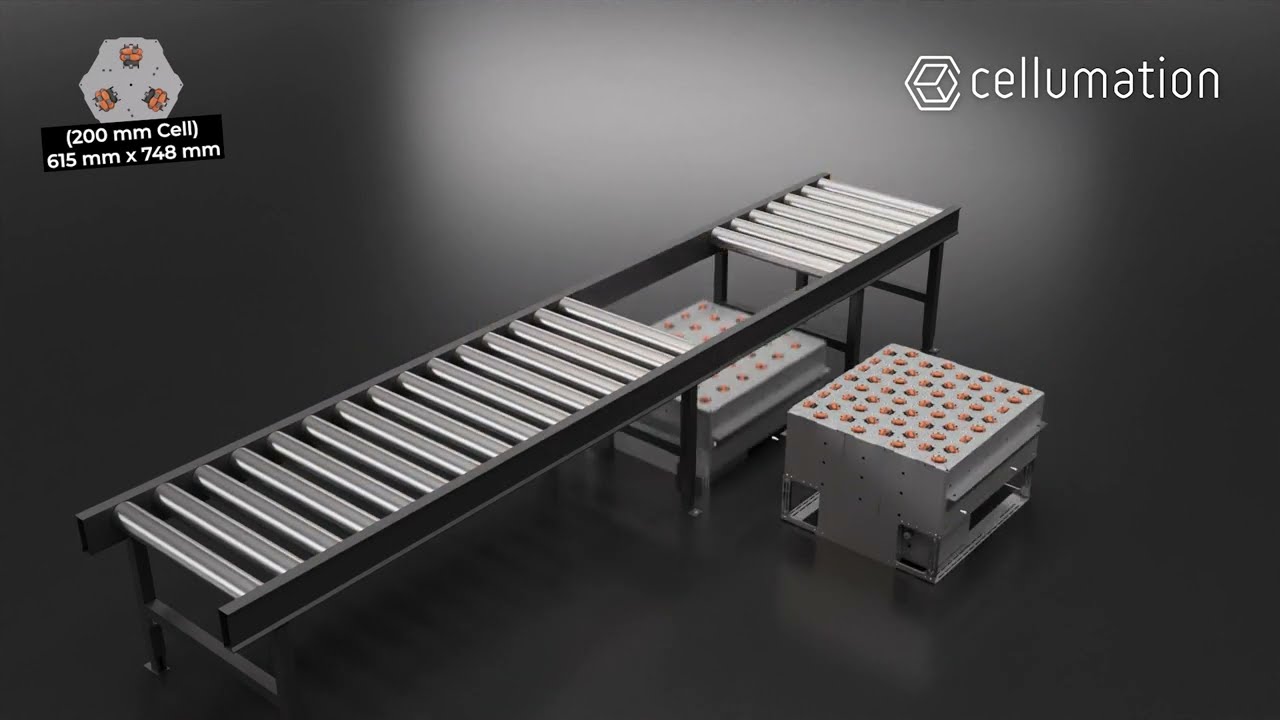

fast integrated

The cv.GO is ready for use within 30 to 60 minutes and fits seamlessly into your conveyor system.

easy to maintain

The robust main component of the cv.GO is the celluveyor cell. It can be replaced in less than 5 minutes.

The cv.GO is . . .

multi functional

16 individually assignable memory slots allow absolute flexibility of movement.

powerful

The cv.GO conveys precisely, quickly and in all directions (from 0 to 360°) at 1.15 m/s.

modular expandable

The size of the cv.GO is freely selectable. Depending on the size of the objects, the number of cells can be adjusted.

100% electrical

We never run out of air. The cv.GO only needs 48V and runs completely electrically.

fast integrated

The cv.GO is ready for use within 30 to 60 minutes and fits seamlessly into your conveyor system.

easy to maintain

The robust main component of the cv.GO is the celluveyor cell. It can be replaced in less than 5 minutes.

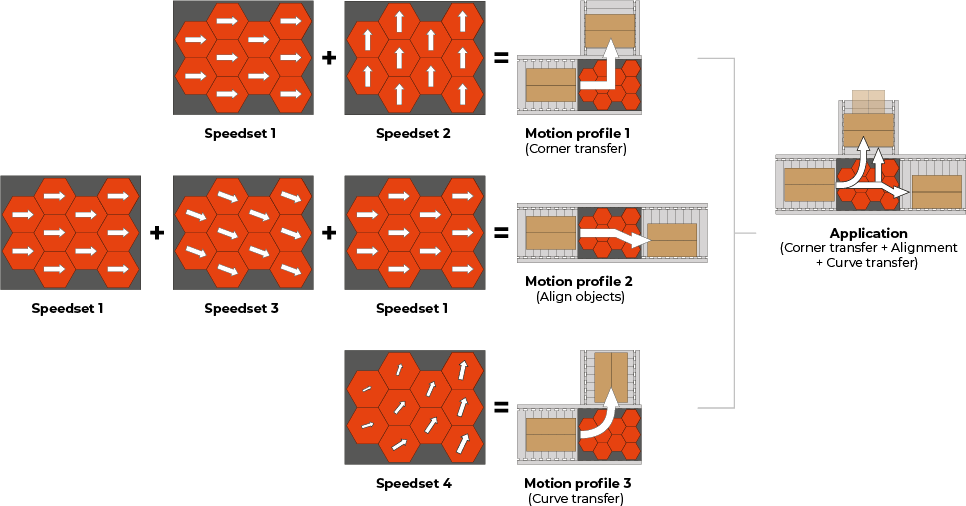

How it works

Speedset: Each cell of the cv.GO is assigned a speed and a direction.

Motion profile: A speedset or the combination of several speedsets results in a motion profile that is in a time sequence.

Application: By defining a motion profile, the cv.GO becomes an application.

Application examples:

- Corner transfer (left / right)

- Diverting, infinitely variable 0 – 90° (left / right)

- Rotation (left / right)

- Align objects in flow direction

- pre-sorting left / right

- many more …

Speedsets, motion profiles and applications can be easily defined through a graphical user interface.

The speedset library enables quick configuration for the required application.

Application example: Conveyed objects are transferred to another conveyor belt with the long or short side, as required. At the same time, the objects are moved straight ahead and aligned to the side guide.

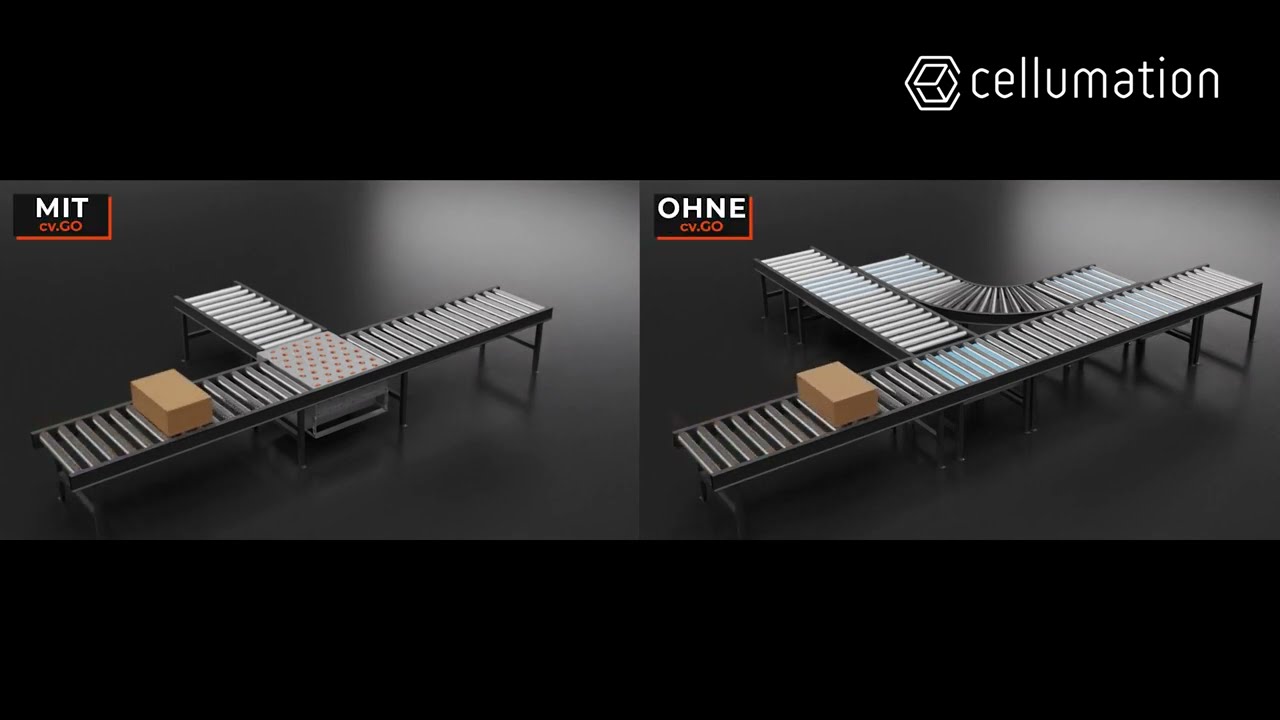

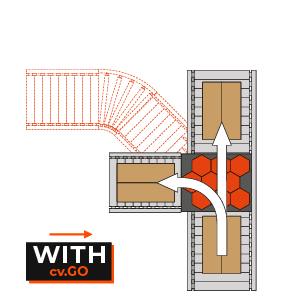

curve transfer

A curve transfer is a world first. The function enables new layout design options with 75 % space and additional hardware savings.

curve & corner transfer

The previous solution for such a conveying problem feels like a workaround. The cv.GO offers through its flexibility new possibilities of layout conception.

Diverter

A complete change of direction in 0.2 seconds, without mechanical stops, is the best remedy against acute signs of wear.

Rotation “on the Fly”

You save 50 % of the space, 70 % of the cost, remain flexible in movement options and increase the performance by 65 %.

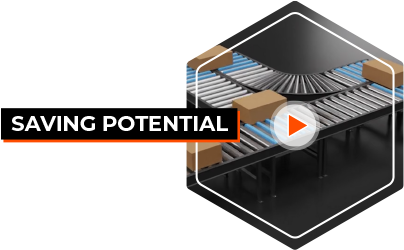

The celluveyor GO offers our customers enormous flexibility and thus great savings potential. Layouts can be optimized, efficiency increased, and the conveyed material moved in a way that is gentle on the object.

You need an individual motion profile?

You are unsure whether the cv.GO is the right solution for your application?

Eligible products

| Underground texture | Flat, firm base Untergrund |

| Minimum size | Cell 150 mm: 150mm x 150 mm Cell 200 mm: 200mm x 200 mm |

| Maximum size | corresponds to the size of the cv.GO-module used |

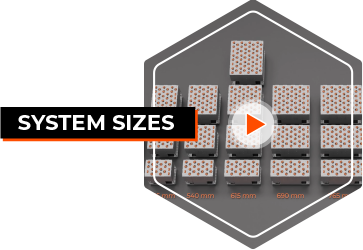

Integration into an existing system

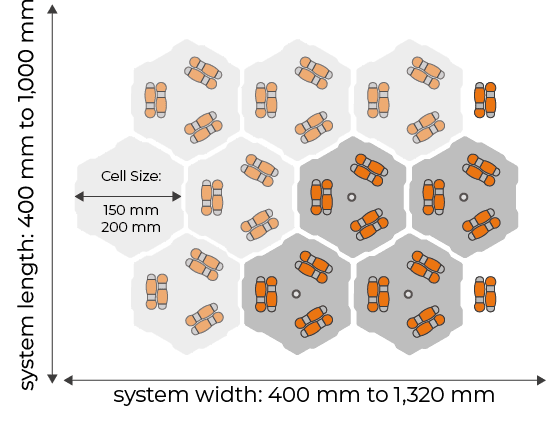

The cv.GO is versatile and the individual cells are reusable. The smallest version of the GO requires only 4 cells, this can be extended up to 18 cells. Thus, you choose a system width (possible: 400 mm to 1,320 mm) or a system length (possible: 400 mm to 1,000 mm) to suit your application.

You choose between two cell sizes (150 mm and 200 mm). This influences, for example, the minimum size of the products that can be conveyed (150 x 150 mm or 200 x 200 mm).

The cv.GO is delivered fully assembled and can be easily integrated into standard conveyor technology – as a plug’n’play product, the system is ready for use in 30 to 60 minutes. Configuration and control is done by you or your integrator. Thus, you have all the freedom of a celluveyor, can use the system in a variety of ways and are independent in its application.

The cv.GO is simply integrated into the existing conveyor system without a base frame. Objects require a flat base for proper transport on the celluveyor.

Significant savings potential

While ordering, the spectrum ranges from min. 4 cells to max. 18 cells for the cv.GO. The price is different for each technical specification, therefore the price of the cv.GO varies depending on the version. However, compared to other systems and the multiple applications, costs can be significantly reduced by optimizing layouts and increasing efficiency.

Let’s talk!

Let’s talk about how we can achieve the highest performance in your material flow system with our powerful celluveyor GO.

Tel. +49 (0) 421 331135 0

Fax +49 (0) 421 33 11 35 99

Mail info@cellumation.com

Kleiner Ort 7

28357 Bremen

Germany

Legal notice & Jobs