The celluveyor:

Modular conveyor technology for flexible material flow

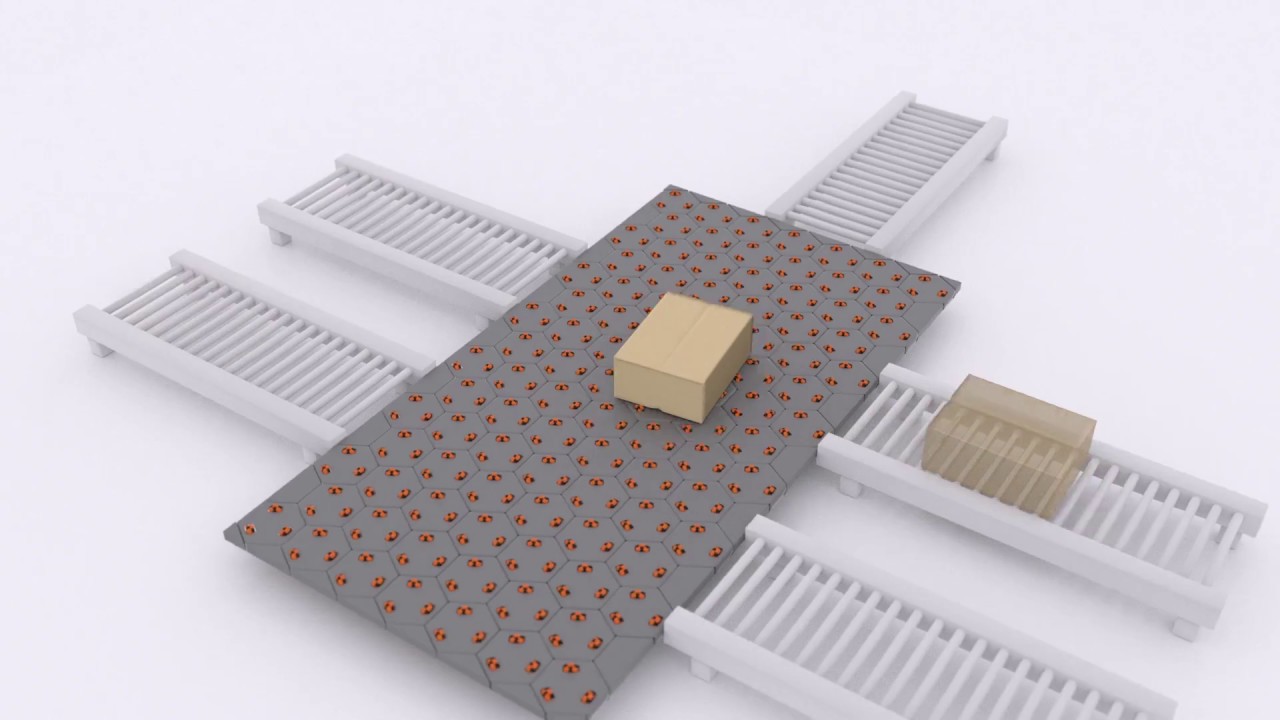

Flexibility, performance and adaptability are the core requirements for the material handling systems of the future. We have developed a flexible system with our robot cells. The hexagonal cells of the celluveyor can be assembled into any layout. The software brings the cells to life. This is why we speak about “softwarebased conveying”.

Benefits of the celluveyor

Robust

A single cell cannot move a product, many cells can move houses. Thanks to their modular design, celluveyor systems are particularly robust and extremely durable. Of course, they are protected against dust and splash water (IP54).

Redundant

Due to the hexagonal construction, our cells are 6-fold redundant. If one cell fails, the surrounding cells take over and transport the passenger to the correct location without downtime.

Expandable

Collaboration is king: Thanks to the cooperation between the robot cells, they can move objects freely and independently over longer distances and perform the most complex tasks simultaneously.

One cell for all tasks

The wheels are omnidirectional (omniwheel) and are standard equipment for many robot soccer teams.

Honeycombs also consist of hexagonal structures. The design allows strong structures and a lot of flexibility.

All wheels are driven independently from each other. The cell receives the impulses through software.

The robot cells are designated with the IP54 degree of protection. Overall, the celluveyor does not have to be kept in a cage, so it is accessible 360 degrees.

Simple & compact

Identical cells – without the need for additional mechanical elements.

Space saving & flexible

Omnidirectional movements enable efficient material flow. Changes in layout and functionality possible at any time.

Transportable objects

Any type & size, as long as the object floor is almost flat.

Min. size of the objects to be transported

150 Cell: 150mm x 150mm

200 Cell: 200mm x 200mm

Maintenance in under 5 minutes

Uncomplicated maintenance, as only one spare part is required – the cell.

Speed

Up to 1.15 m/s

Why is flexibility a game changer?

Common conveyor technology has the advantage of being able to handle simple conveyor tasks, such as moving objects in a straight line. For more complex tasks (e.g. rotating, descrambling and sorting), the conveyor technology has to be extended by additional mechanical components up to industrial robots. This results in highly specialised systems that can perform these specific tasks particularly efficiently but lose flexibility.

In addition to the technological requirements, the newly acquired automation and material flow system must pay for itself within a short period of time, as short-term changes in the order situation or production schedule may require corresponding adjustments to the functionality or even the layout. For this reason, conveyor system flexibility is becoming increasingly important, as it allows companies to respond quickly to new needs and changes in order volume.

The ability to move multiple objects simultaneously and independently omnidirectionally through the hexagonal robot cells, as well as the modular design, the high adaptability of the system to new tasks, and the small footprint meet key requirements for the material handling systems of the future.

The cellular approach and intelligent control offer users and system integrators flexibility on various levels. In addition to layout flexibility as well as process flexibility, the “celluveyor” also allows for high throughput and unique material handling flexibility, without changeover times.

celluveyor stands for cellular conveyor!

It is the result of several years of research and development work. It is based on a simple idea: The robotic cells do not move themselves, but instead form an intelligent surface that uses swarm intelligence to bring the transported goods to their desired destination.

How does the celluveyor work?

The modular conveying and positioning system consists of small hexagonal modules containing specially arranged omnidirectional wheels, each of which is individually and specifically controlled. This allows us to move or position multiple objects on any path at the same time and independently of one another. In this way, complex material flow tasks, which are nowadays realised by very large systems, can be carried out in the smallest possible space.

What is special about the “celluveyor“?

The celluveyor combines the efficiency of automation systems with the flexibility of manual processes. It is a high-performance conveyor technology that can be used universally in principle. Thanks to the intelligent control system and the modular concept, the celluveyor can be expanded and adapted to new requirements without great effort.

Applications

cv.DEPAL

cv.GO

Nico Loibersbeck

Sales

We love our technology and love to talk about it. There are still questions open?