Increasing efficiency in logistics: Covivins optimizes warehouse processes with innovative automation technology from cellumation

Press release

Bremen, 27.08.2024

Belgium-based Covivins, a leading supplier of alcoholic beverages with over 5,000 products in its range, has recently taken a significant step towards optimizing its internal logistics processes. With the support of renowned intralogistics integrator Ceratec, the entire warehouse was automated to meet the increasing demands for efficiency and scalability.

A key element of this modernization is the integration of cellumation’s celluveyor DEPAL, a modular and innovative solution that is particularly effective when handling sensitive products.

Covivins supplies over 1,000 wholesalers and specialist stores both in Belgium and internationally. Customers benefit from a comprehensive service that includes the ordering, storage and delivery of products. With the automation of the warehouse and the implementation of celluveyor DEPAL, Covivins has been able to significantly increase efficiency in processing and storage, which contributes to faster delivery, especially with high order volumes.

Challenges und Solutions

The main challenge in automation was to efficiently process the wide variety of products – over 5,000 different items. The solution: a state-of-the-art system that makes it possible to depalletize pallets with mixed products and align the products precisely without knowing the exact dimensions of the individual items in advance. This task is performed by the celluveyor DEPAL in combination with a gripper arm robot and a 3D vision system. After separation, the products are stored in a high-bay warehouse and prepared for further dispatch.

Technical Highlights

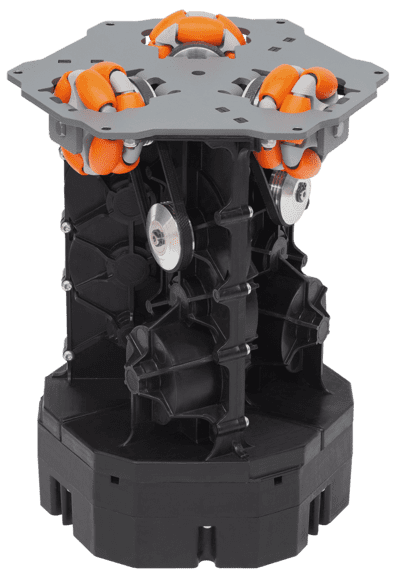

The integrated system consists of the celluveyor DEPAL Double, which is equipped with 105 hexagonal robot cells and is capable of precisely separating and aligning the products. Thanks to standardized interfaces and preconfigured systems, the integration went smoothly and quickly. A special feature is the “Passenger Exit Timing” function, which ensures that each product leaves the system with optimum timing and thus prevents collisions during transportation.

With an output capacity of up to 1,200 products per hour on the main conveyor belt and a special function for the slow and safe movement of tilt-heavy items, the celluveyor DEPAL ensures a reliable and efficient process chain.

Future-proof and scalable

Thanks to the flexible and scalable technology of the celluveyor DEPAL, Covivins can easily expand its product portfolio in the future without having to make any adjustments to the logistics system.

„For unloading, we found the gripper and for alignment we worked with cellumation and opted for the celluveyor. First of all because of its small footprint, also because of the possibility of aligning the products without knowing the configuration of the products in position and without knowing the dimensions of the products. That was a big advantage”

“The space saving of 95% compared to conventional solutions is a decisive advantage that we can offer our customers. As a result, up to 45 additional pallets can be stored unstacked on the freed-up space, which can make their way to the customer more quickly. We are proud of the successful project at Ceratec and Covivins, which impressively demonstrates these benefits.”

The successful implementation of the celluveyor DEPAL underlines the innovative strength of Covivins and Ceratec and sets new standards in warehouse automation.

Theresa Gröninger

Head of Marketing & Business Development

Are you interested in taking a look behind the scenes? Would you like to find out more about cellumation?

About cellumation GmbH

Founded in 2017, cellumation GmbH develops and manufactures intelligent modular technologies for automated material flow. The intelligent software brings hexagonal robot cells (the celluveyor) to life in the smallest of spaces. The cells can be assembled into any layout, handle complex conveying tasks and transport different goods without changeover times. The company’s vision: in future, every parcel delivered worldwide should have touched a cellumation cell. To achieve this goal, over 60 employees from 13 nations work, develop, grow and produce hand-in-hand at the Bremen site.

Let’s talk!

Let’s talk about how we can achieve the highest performance in your material handling system with our powerful celluveyor technology.

Tel. +49 (0) 421 331135 0

Fax +49 (0) 421 33 11 35 99

Mail info@cellumation.com

Kleiner Ort 7

28357 Bremen

Germany

Legal notice & Jobs