Intelligent conveyor technology for production and logistics

Based on the patented celluveyor technology, cellumation offers powerful automation solutions for material flow systems in intralogistics.

Ready for Asia:

In order to offer our end customers and system integrators in Asia 24/7 pre-sales and after-sales support, we are working together in a strategic partnership with the Melchers Group.

The Bremen-based group of companies specialises in opening up international markets and has been active in Asia for over 150 years.

CONTACT

Get in touch with our experts in asia

South Korea

| Mr. James Seong – Sales Manager james.seong@korea.melchers.de Phone: +82 2869 5395 Mobile: +82 10 2579 5223 |

|

Rest of Asia

| Mr. Norbert Woebs – Sales Manager n.woebs@cellumation.com Phone: +49 421 3311 3545 Mobile: +49 151 2807 1828 |

|

Powerful

Omnidirectional movements enables efficient material flow, at up to 1.15 m/s.

Space-saving

5 hexagonal cells are sufficient to provide a multitude of complex material flow movements.

modular

The flexible arrangement of identical cells creates unlimited layout possibilities and extensions.

Quickly integrated

We integrate in a few days, not weeks.

We make You move Our Mission

Our goal is to push the boundaries of what has been technically possible until now to a new, more efficient level. With our high-performance and universally applicable celluveyor technology we are revolutionising the world of conveyor technology and helping to optimise the material flow. Our vision:

In the future, every package delivered worldwide will have touched a celluveyor cell.

Technology

What is the celluveyor

“cellular conveyor”

The idea behind the celluveyor is a modular conveying and positioning system that is fundamentally based on a single component – the cell. The hexagonal design of the hardware module promises flexible layout options. In combination with the three omnidirectional and independently driven wheels per cell, complex material flow movements are possible with minimal space requirements. For this purpose, our intelligent and self-learning software brings the cells to life and individually controls the wheels, so that objects can be aligned or even rotated as desired. The principle is simple: The hardware remains the same, the software defines the function.

Products

Our product names combine the hardware with the software. “cv.” is the abbreviation for celluveyor and with the appropriate software we create products for a wide range of applications.

cv.DEPAL

Separate any pallet layers automatically, on less than 3 square meters and on up to three exits.

cv.GO

The all-rounder for your conveying system: corner transfer, rotation, curve travel, diverting – precise & fast.

cv.CROSSDOCK

From small turnouts to large sortation solutions, the cv.SORT can be scaled to any size & allows for high throughput, with automated alignment of the conveyed material.

cv.BULKSORT

The answer to growing e-commerce and limited logistics space.

3 processes in one cv.BULKSORT:

Singulate, orientate & sort.

Latest projects

cv.SORT at DHL

Sorting, rotating and aligning on less than 3 m². Together with FS Solutions, cellumation has integrated a high-performance sorting solution at the DHL Logistik Center Greven, which has enabled a significant increase in throughput.

cv.SORT at Verdnatura

428 cells, 11 meters, 10 synchronized cameras and 34 bidirectional buffers.

As a key component of the warehouse automation, a celluveyor XXL sorts and sequences all orders, for optimal palletizing.

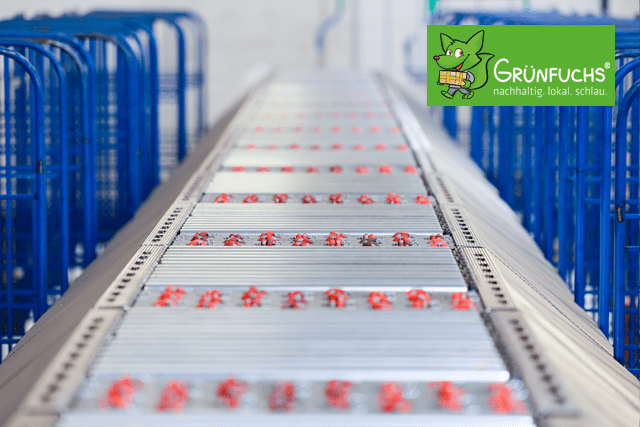

CMILE – Last Mile

Space-saving sorting in the Microhub, ensures less CO² emissions on the last mile. Together with Grünfuchs, we were able to successfully realise the pilot project.

This required a combination of our systems.