6 reasons why the modular celluveyor reduced the chaos in the warehouse

Simple, fail-safe, flexible, compact, quiet and unique: In this article, we have summarized six reasons why the celluveyor as a modular conveyor technology reduces chaos in the warehouse. Online shopping, Corona and global flows of goods: Warehouses are currently in a pre-Christmas mood all year round. In order to continue to cope with the enormous pressure of e-commerce, the automation of processes in warehouse logistics is unavoidable.

Simplicity

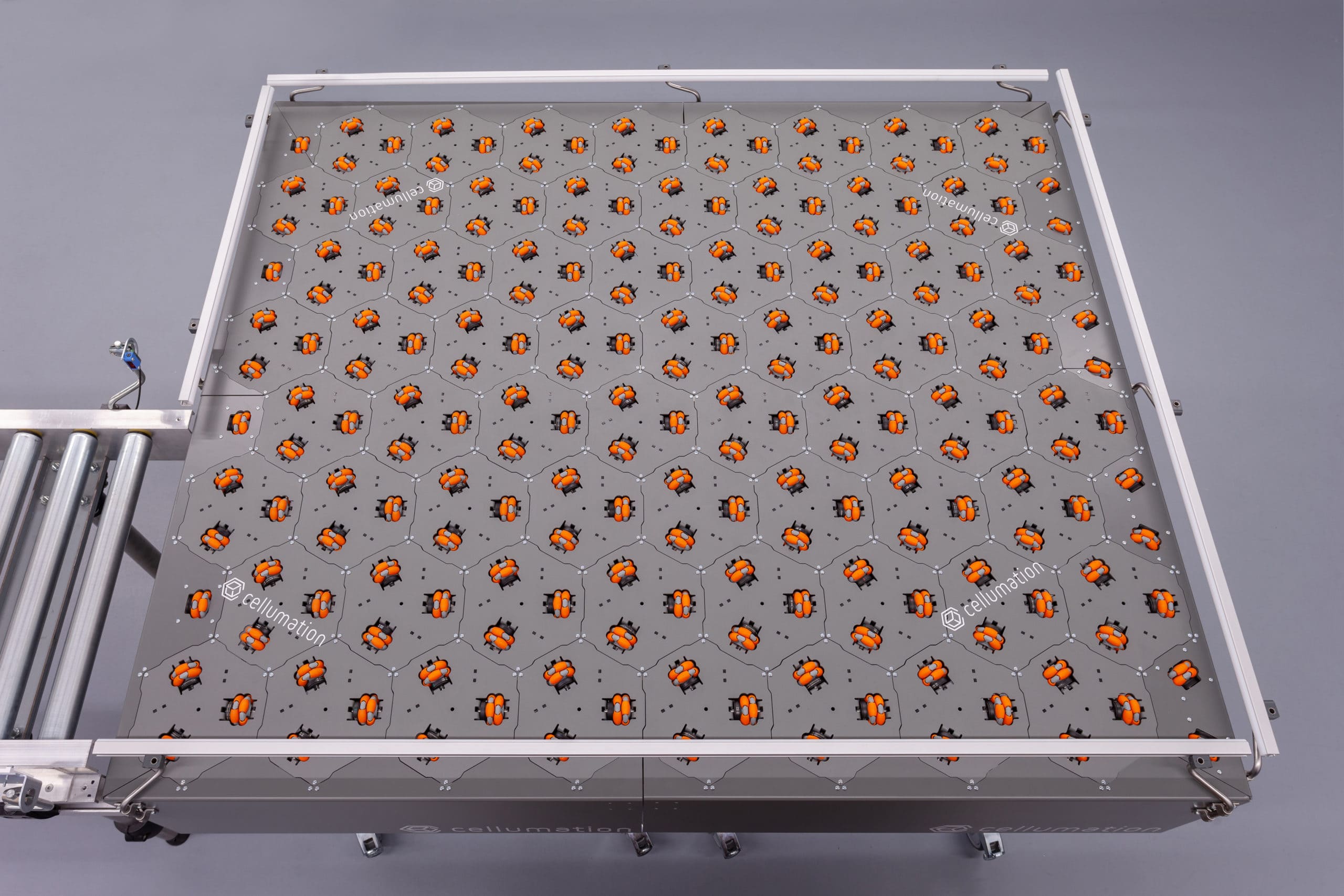

Keep it simple! Our hardware consists of identical cells – without the need for additional mechanical elements. Due to their hexagonal shape, different layouts can be flexibly realized. Since the functionality of the cell is defined by software alone, the hardware always remains the same – regardless of which application the celluveyor is running.

Our technology describes the symbiosis of hardware and software. With the help of the software, the cells can communicate with each other, thus each cell knows its position on the table and when it needs to set its omnidirectional wheels in motion.

Simplicity

Safe in operations

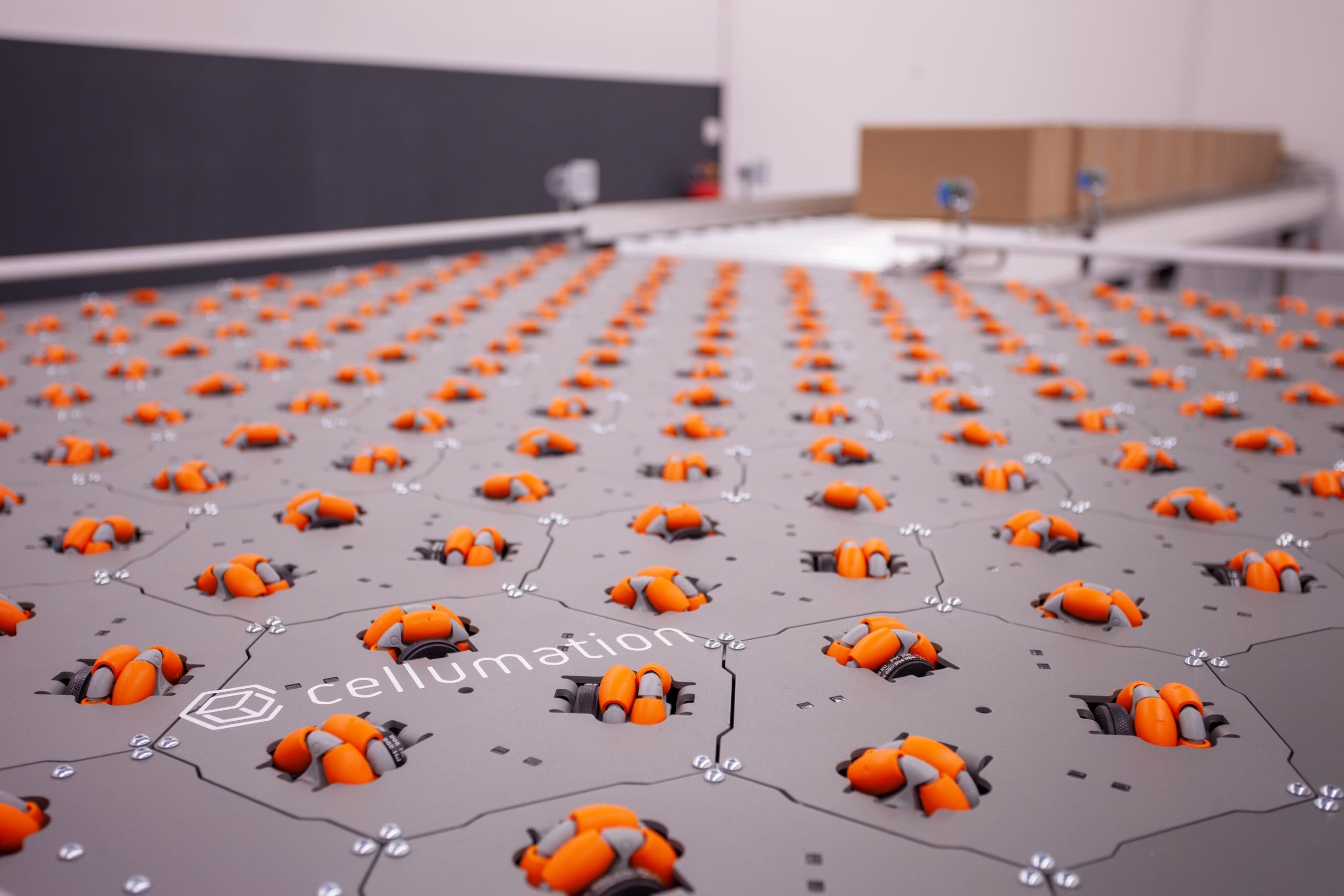

Our cells are designed for at least 50,000 operating hours. Due to the redundant design with identical modules, the system is fail-safe. The cells are robust, durable and have a protection rating of IP 54. This means that they have full protection against contact and are protected against dust and splash water.

One benefit of our modular design with hexagonal cells is 6-fold redundancy. This means that if one cell fails, the surrounding 6 neighboring cells can step in. The vision system reacts immediately and counteracts accordingly.

Of course, we initially offer support without travel time. By “softwarebased conveying” most problems can be solved by remote diagnosis and software updates. Thus, on-site operations become rare encounters.

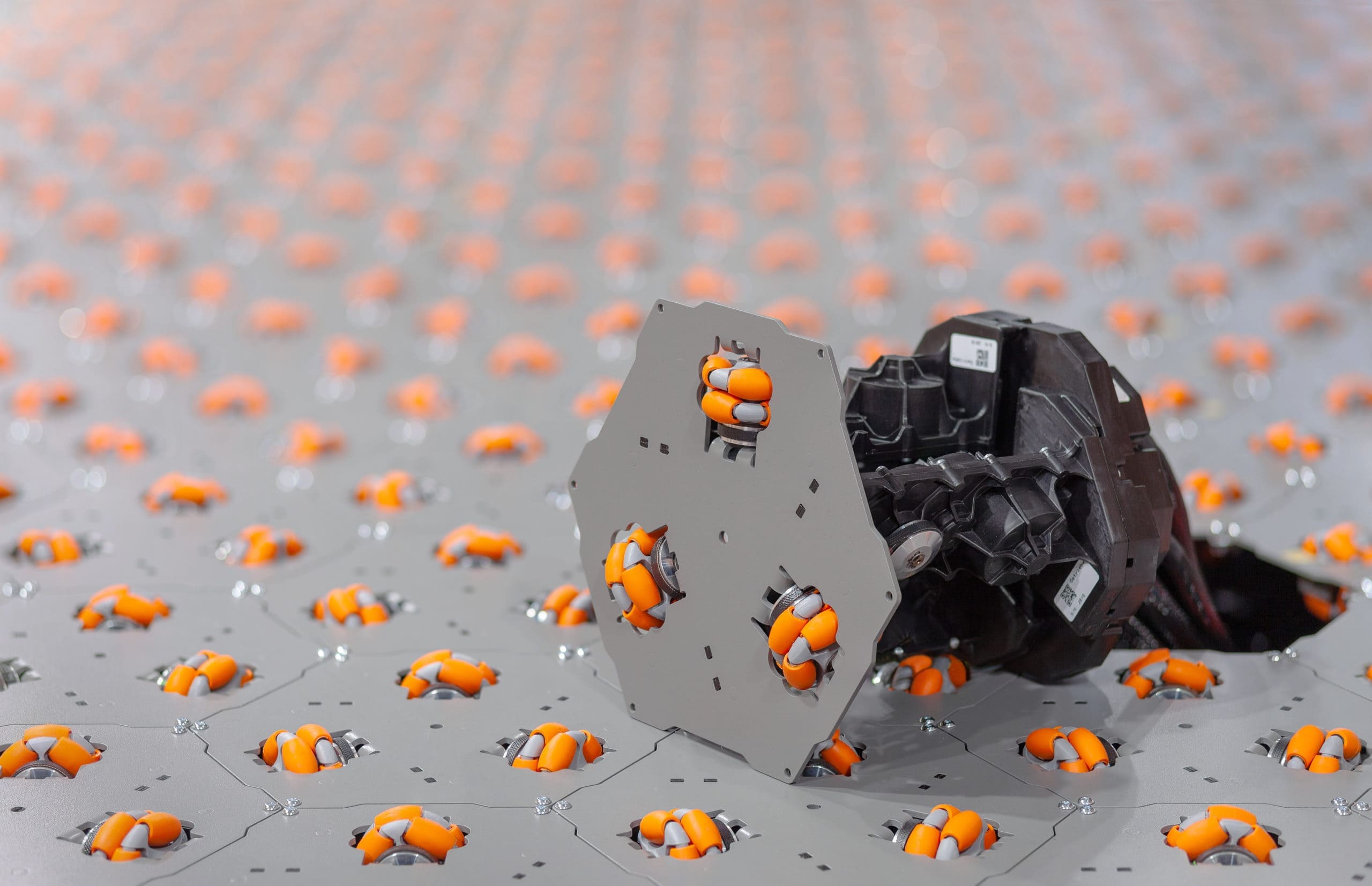

Uncomplicated assembly & maintenance

Standing machines, for example due to a rebuild, are like a broken ice cream machine at the golden fast food giant: not satisfying. For this reason, we have made the set-up time efficient and short: The celluveyor can be set up in a flash and integrated within two days in most cases thanks to plug’n’play.

In addition, maintenance is surprisingly straightforward, requiring only a single spare part, a robot cell and a screwdriver. A cell exchange takes less than five minutes and can be carried out cost-effectively and without our support.

Uncomplicated assembly & maintenance

High flexibility

The celluveyor is software-driven materials handling technology: With our cell concept, we can map all material flow functions with a single technology. While our products differ in their applications, everything is based on the same hardware. The software defines the function.

Do you want to increase or decrease the capacity or operate additional inputs or outputs? – No problem The celluveyor is like a highway: the more lanes that can be traversed simultaneously, the more objects that can be handled at the same time, and the higher the performance. Thanks to the modular design, areas can be easily expanded or additional inputs and outputs added.

High performance

with minimum space requirement

The individual wheel control of our cells enables objects to be rotated individually while moving freely in all directions, simultaneously. This technology allows even the most complex material flow tasks to be efficiently realized in a small space.

Thanks to the remarkable variety of movements and the ability to execute processes simultaneously, we achieve high throughput with minimal space requirements.

High performance

with minimum space requirement

Quiet!

Noise can be very stressful for employees. Our celluveyor is only <70 decibels quiet and thus comparable to the noise level in an open-plan office. For this reason, it is possible to work directly next to the conveyor system even without hearing protection.

We see flexibility, performance and adaptability as core requirements for the material handling systems of the future. They are always in the focus of our considerations. Due to steadily increasing logistics volumes and ever more expensive space, systems must also be space-saving and reliable. Time is money: The integration of the conveyor systems of the future must be realized quickly in order to avoid prolonged downtime of the conveyor lines during the conversion phase. The celluveyor is our key to mastering future challenges and more automation in material flow.

We love our technology and love to talk about it. There are still questions open?

Theresa Gröninger, Marketing Manager