Practical analysis of the Last Mile – an overview of current studies

The last mile has always been the most cost- and time-intensive delivery process for CEP service providers and automation will be unavoidable in the future. This problem is analyzed in a practical way by current studies and solutions are shown by new technologies and possibilities.

New technologies to solve the last mile problem

The last mile therefore, the last delivery route from the distribution center to the parcel recipient, causes many CEP service providers (courier, parcel, express) a headache again and again in practice. For every delivery that requires two or more delivery attempts you are operating at a loss. To make matters worse, there are more and more driving bans and environmental zones in inner cities. At the same time, politicians want Co2-neutral and traffic-calmed city centers.

Little space for new logistics centers in cities.

Experience also shows that real estate for inner-city distribution centers is becoming increasingly scarce and expensive, so they are moving further and further away from the city center and thus the largest parcel volume. This is particularly true because the volume of parcels can only be handled at all by ever expanding large distribution centers. The result: longer, more cost-intensive and ecologically flawed transport routes.

The BIEK-KEP Study 2021 highlights this steadily increasing problem. In 2020, the volume of parcels in Germany increased by 10.9% from 3.659 billion to 4.05 billion shipments, a double-digit increase for the first time. Furthermore, B2C shipments increased by 18.6%. The previously expected volume of shipments for 2025 will already be reached in 2022. It is clear that a steady increase in the size of distribution centers and manual sorting of parcels will not be a long-term solution to the ever-increasing volume of parcels.

Little space for new logistics centers in cities.

Experience also shows that real estate for inner-city distribution centers is becoming increasingly scarce and expensive, so they are moving further and further away from the city center and thus the largest parcel volume. This is particularly true because the volume of parcels can only be handled at all by ever expanding large distribution centers. The result: longer, more cost-intensive and ecologically flawed transport routes.

The BIEK-KEP Study 2021 highlights this steadily increasing problem. In 2020, the volume of parcels in Germany increased by 10.9% from 3.659 billion to 4.05 billion shipments, a double-digit increase for the first time. Furthermore, B2C shipments increased by 18.6%. The previously expected volume of shipments for 2025 will already be reached in 2022. It is clear that a steady increase in the size of distribution centers and manual sorting of parcels will not be a long-term solution to the ever-increasing volume of parcels.

Delivery recipient requirements in practice

Every parcel recipient knows this: the parcels always arrive when you are not at home and is then delivered to the parcel station or another delivery attempt is made the next day. This requirement profile is also confirmed by the capgemini study. In this, 59% of consumers saw the prices as too high, on the other hand 49%, reject delivery services due to a lack of same-day delivery. In addition, 47% are dissatisfied due to frequently late deliveries. A clear picture of consumers’ needs emerges they want faster, more frequent, and more reliable deliveries and preferably on the same day. If these characteristics were given, they would also be willing to spend more money.

Delivery recipient requirements in practice

Every parcel recipient knows this: the parcels always arrive when you are not at home and is then delivered to the parcel station or another delivery attempt is made the next day. This requirement profile is also confirmed by the capgemini study. In this, 59% of consumers saw the prices as too high, on the other hand 49%, reject delivery services due to a lack of same-day delivery. In addition, 47% are dissatisfied due to frequently late deliveries. A clear picture of consumers’ needs emerges they want faster, more frequent, and more reliable deliveries and preferably on the same day. If these characteristics were given, they would also be willing to spend more money.

Ecological design of the last mile

Looking at the global trend towards saving the climate and sustainability, so far there is no established technology or last mile models that allow for ecological design. As a result, the last mile is increasingly becoming the problem child of the entire logistics industry. The solution could be so trivial, however in that smaller companies or technology start-ups are increasingly moving into the focus of the large logistics companies and are being considered.

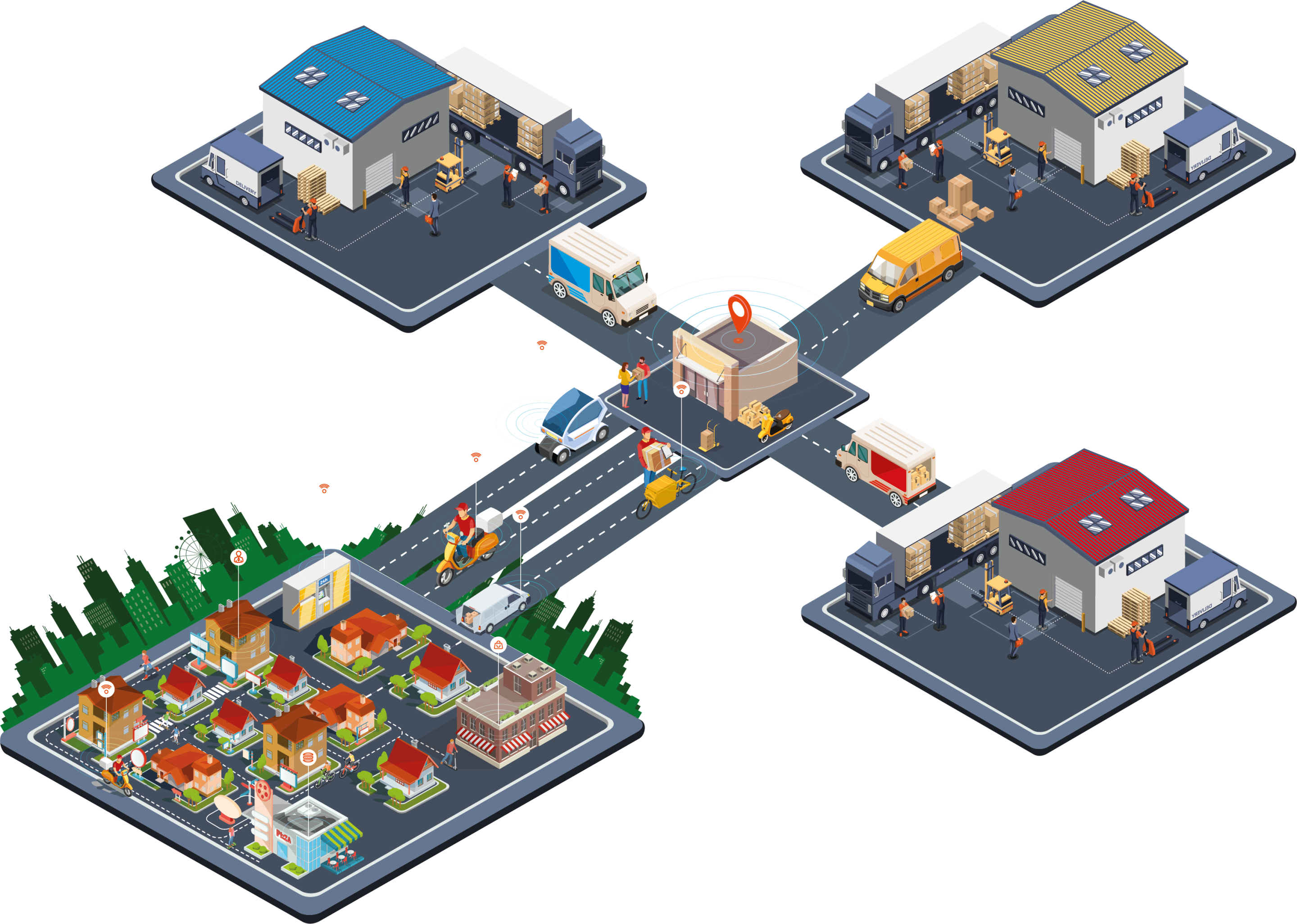

Solution through local micro-solutions in the neighborhoods?

The only way to overcome the problems listed above in reality is to place micro-solutions, so-called “microhubs,” at parcel hotspots. Here celluveyor technology can be used to sort parcels in the smallest of spaces. The modular and intelligent conveyor technology convinces with high space and cost savings in different applications. Likewise, inner cities would become more attractive by having less traffic and thus more space in narrow streets. In addition, time-consuming and expensive deliveries to parcel recipients would be optimized.

Freight bikes between hub and parcel recipient

Transport from the hub to the recipient could be achieved, for example, by companies such as the Bremen-based manufacturer Rytle. Rytle specializes in the development of cargo bicycles and has already designed various models for different applications. These are already being used in practice and thanks to their electric drive, reach zones where car traffic is limited or prohibited due to low-emission zones. At the same time, they allow longer delivery times and thus correspond to the model of multiple daily delivery as well as same-day delivery. But they also relieve the pressure on roads and traffic in city centers and shorten the delivery person’s route to the door. Drivers do not need a driver’s license to move cargo bikes. A load of up to one Euro pallet or 180 kilograms is possible. However, the delivery routes must not be too long, otherwise cargo bikes are too slow. Here, the solution is offered by so-called “micro-solutions”. These are then set up near parcel hotspots to cover the optimum delivery range of 10km.

Already many practical projects in the city center of Bremen look promising and show that a reliable delivery by cargo bike is possible.

Freight bikes between hub and parcel recipient

Transport from the hub to the recipient could be achieved, for example, by companies such as the Bremen-based manufacturer Rytle. Rytle specializes in the development of cargo bicycles and has already designed various models for different applications. These are already being used in practice and thanks to their electric drive, reach zones where car traffic is limited or prohibited due to low-emission zones. At the same time, they allow longer delivery times and thus correspond to the model of multiple daily delivery as well as same-day delivery. But they also relieve the pressure on roads and traffic in city centers and shorten the delivery person’s route to the door. Drivers do not need a driver’s license to move cargo bikes. A load of up to one Euro pallet or 180 kilograms is possible. However, the delivery routes must not be too long, otherwise cargo bikes are too slow. Here, the solution is offered by so-called “micro-solutions”. These are then set up near parcel hotspots to cover the optimum delivery range of 10km.

Already many practical projects in the city center of Bremen look promising and show that a reliable delivery by cargo bike is possible.

Profiteers retail trade and city centers

Retailers could also benefit from automated micro-solutions. They could sell goods outside its opening hours via an online store. The click and collect model previously created during the Corona pandemic becomes a click and delivery model, providing a second marketing opportunity for retailers. At the same time, customers with large purchases no longer have to carry bags, as their purchased goods could be delivered to their homes on the same day. This results in a strengthening of the retail sector and counteracts the extinction of the city centers.

Technological progress enables efficient processes

If you want to invest in future-oriented technical solutions for the last mile, the celluveyor offers the possibility to solve the problems through its versatile layout variations, adapted to the local conditions. A space-saving, cost-efficient and fast design of the last mile, in which all involved parties win, can only be achieved by automating sorting processes. In the future, automation will be mandatory and the celluveyor offers every possibility to put this into practice. This conveyor technology is the missing piece of the puzzle to change the last mile sustainably, economically and efficiently.

Our solution for the last mile – cv.BULKSORT

cv.BULKSORT

cv.DEPAL

cv.GO

Dogan Kirhan

Sales

Our space-saving technology is a game changer for inner-city logistics. We look forward to discussing our ideas with you.